Hello! To all the future technology enthusiasts out there, in this week’s “Innovation Per Week,” I’m excited to introduce our cutting-edge AI learning type visual inspection software, “AI-Detector Pro.” This is not just any inspection tool. It’s like magic, revolutionizing manufacturing lines! Let’s dive together into the world of this innovative technology!

AI-Detector Pro: The future of inspection

“AI-Detector Pro” is equipped with advanced AI that can learn from as few as 100 images. This enables it to accurately detect random defects in shape or size, such as scratches, burrs, and dents. Additionally, as more training images are added, the software’s proficiency improves, allowing for more precise inspections.

Features of AI-Detector Pro

High precision inspection: Learns from just 100 images and doesn’t miss random defects.

Ease of use: No cloud needed, no expertise required, making it accessible for anyone to use easily.

Upgrade path: Smooth upgrade from a feature-limited version, “AI-Detector Pro Test.”

However, there are some drawbacks…

Training time: Learning takes time, so if you desire a rapid implementation, patience is needed.

Resource demand: Requires a high-spec PC, which necessitates careful planning.

Here’s a comparison between the AI deep learning visual inspection software (AI-Detector Pro) and pattern matching visual inspection software (EI710).

|

AI deep learning visual inspection software (AI-Detector Pro) |

Pattern – matching visual inspection software (EI710) |

|

|

Counting Items |

◎ |

× |

|

Detection of Random Defects |

○ Pattern extraction is performed on registered images, allowing for the prediction and assessment of similar ones |

△ Comparisons can only be made with registered images |

|

Sample positioning |

○ By registering images with various patterns such as rotation and positional shifts, adaptability can be achieved. |

△ |

|

Capable of handling good products with variations. |

○ |

× |

|

Master registration image |

100 images~ The more varied the patterns registered, the greater the proficiency. |

1 images |

|

Dimensional measurement |

× |

○ |

|

Color determination |

△ |

○ |

|

Multi-camera support |

△(Customize) |

○ |

|

|

× |

○ |

Sample – specific case studies

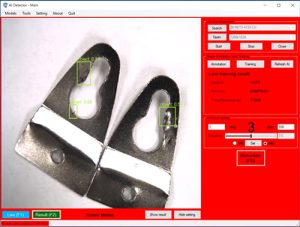

- Burr inspection for metal products

In the world of metal fabrication, minute burrs on products can pose significant issues. However, fret not! “AI-Detector Pro” employs its advanced image analysis capabilities to instantly detect these minute burrs. This eliminates the need to manually address tiny, visually undetectable burrs.

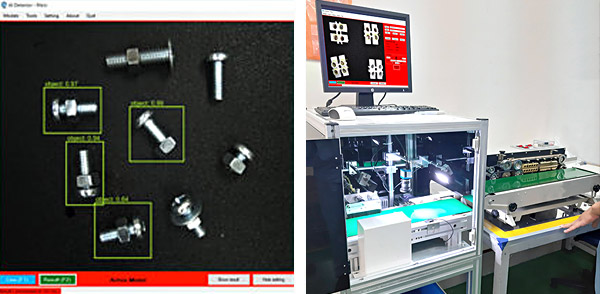

2. Counting objects with identical features

Counting thousands of parts, such as screws or bolts, which share the same characteristics, can be a monotonous and exhausting task for humans. Once again, “AI-Detector Pro” comes into play. It provides accurate counts in an instant, significantly reducing the time and effort required for counting.

3. Presence of components in plastic terminals

In the assembly of electronic components, ensuring that small parts like plastic terminals are accurately placed is crucial to the product’s performance. Here, “AI-Detector Pro” utilizes its precise inspection capabilities to automatically check for any missing components, significantly reducing the risk of defective products.

4. Inspection for presence of nuts in screw + nut assemblies

On assembly lines, screws and nuts are often used together, but a missing nut can compromise the overall safety of the product. “AI-Detector Pro” detects such assembly errors in real-time and reliably alerts operators.

| Supported OS | Windows10(64bit) Version 1809 |

|---|---|

| CPU |

Intel Core i7 or higher RAM: 16GB or more |

| GPU |

NVIDIA CUDA-compatible GPU required ※NVIDIA RTX2070 6GB or higher (CUDA compatible) |

| Supported cameras |

USB3 Vision cameras CS series, GigE cameras EG series |

Additionally, we introduce practical applications.

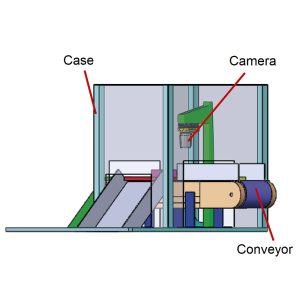

AI Automatic presence inspection system: Automatically inspects for the presence of components and instantly identifies defects.

AI automatic counting system: Automatically counts the exact number of products, enhancing quality assurance.

To fully utilize this system, specific hardware is required.

USB cameras and lenses: Various cameras and lenses are available for optimal image acquisition.

|

|

I/O Unit: Facilitates integration with PLCs and sequencers, supporting automation of production lines.

Automatic backup HDD: Ensures safe backup of training data and facilitates easy recovery.