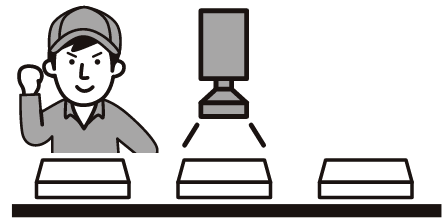

High-precision measurement system for metal plates using a camera

Product Features

Measurement of 600 types of products with different dimensions (maximum product length 1000mm)

Read the barcode on the product and switch the measurement program.

Measurement item

Total length, hole diameter, distance between two circle centers

Using bilateral telecentric lens, the total length is measured in parts and the total dimensions are displayed.

-

Only one

Only one

-

Hardware

Hardware

-

Software

Software

Features 2D VISION MEASUREMENT SYSTEM

Inspection

Conditions

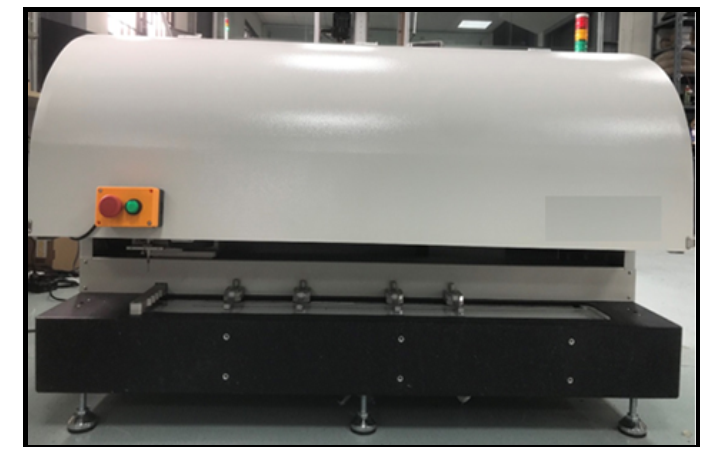

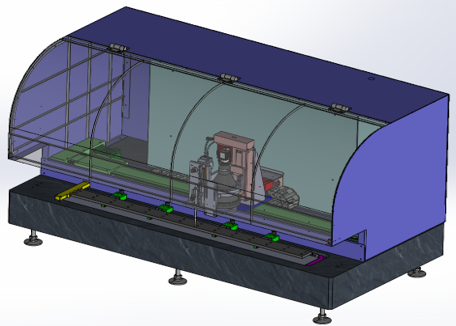

The product to be inspected is made of metal and is extremely affected by external light.

A cover must be used on the system to completely block out external light.

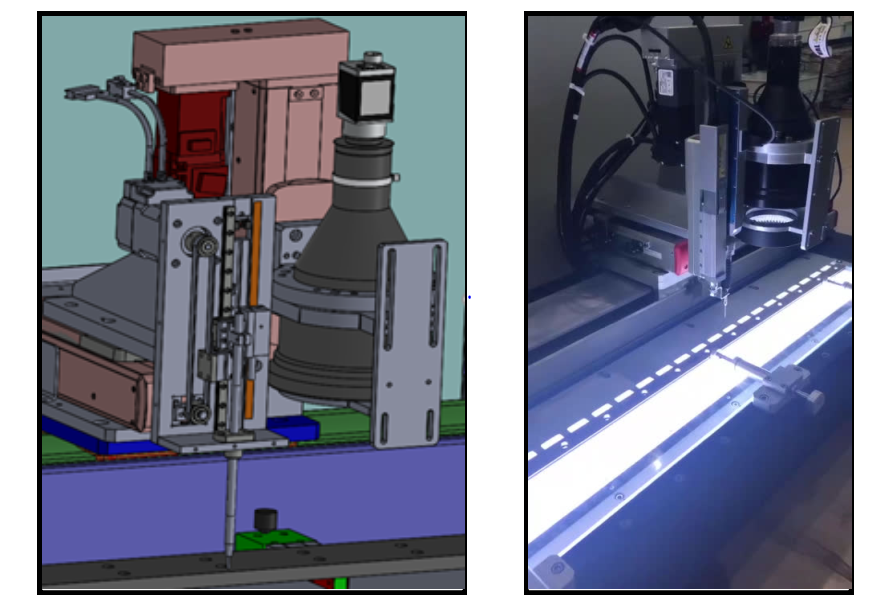

Transmitted illumination is effective because it measures the total length of the inspected product, the diameter of the hole, and the distance between the center points of two circles.

For transmitted illumination, parallel light transmitted illumination is used to prevent light from going around to the inspected product.

System Speed

The inspection time for a product with a total length of 750 mm and 8 holes is 15 seconds.

Hardware

12MP USB camera

Bilateral telecentric lens

Parallel light transmitted illumination

Software

Developed with VisionPro standards

What is a telecentric lens?

There is no expansion or contraction of the image within the depth of field.

Measurement errors can be minimized when measuring dimensions.

Less image distortion due to parallax

There are two main types of telecentric lenses.

Bilateral telecentric lenses and unilateral telecentric lenses.

The features of each are as follows.

Bilateral telecentric lens

It has the characteristic that the projected size of the object does not change regardless of the distance between the camera sensor side and the object side.

In other words, by changing the distance on the camera sensor side using a close-up ring, etc., you can change only the distance between the lens and the object without changing the magnification.

However, the diameter of the lens is physically larger than the area to be projected, so the lower the magnification, the larger the lens size and the higher the price.

Used in precision measuring equipment and projectors.

Object-space telecentric lenses

This lens has a telecentric lens structure only on the object side.

Unlike Bilateral telecentric lens, when the distance to the camera sensor side changes, the projected size of the object changes, similar to non-telecentric lenses.

The lens is smaller and less expensive than Bilateral telecentric lens.

If changing the magnification like a macro zoom lens is not necessary for dimension measurement purposes, it may be used as a fixed magnification replacement.

How to introduce

-

STEP1

Please contact us by phone or E-mail.

-

STEP2

Evaluation of cameras, lenses, and lighting

Although it can be used with commercially available products, we also individually propose products that suit your company.

Demo version:You can download Demo version from here.

We also send CDs to those who cannot download. (Japan only)

Sample test:We accept sample test for free.

-

STEP3

Introduction

Technical blog

-

2021.06.21

Camera technique in Pattern matching visual inspection software EI710

-

2021.06.21

How to use lighting in Pattern matching visual inspection software EI710

-

2021.06.21

How to use the mirror in Pattern matching visual inspection software EI710

-

2021.06.21

Multiple frame operation function in Pattern matching visual inspection software EI710

-

2021.06.18

Presence / absence inspection of specified color: Concept of color judgment allowable range and tips for setting

-

2021.06.18

3 types of trigger modes in Pattern matching visual inspection software EI710