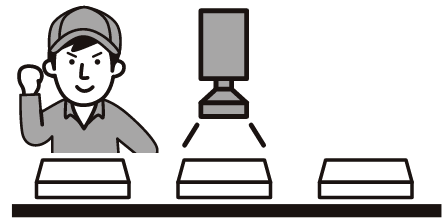

PCB-based 3D scanner measurement system

Product Features

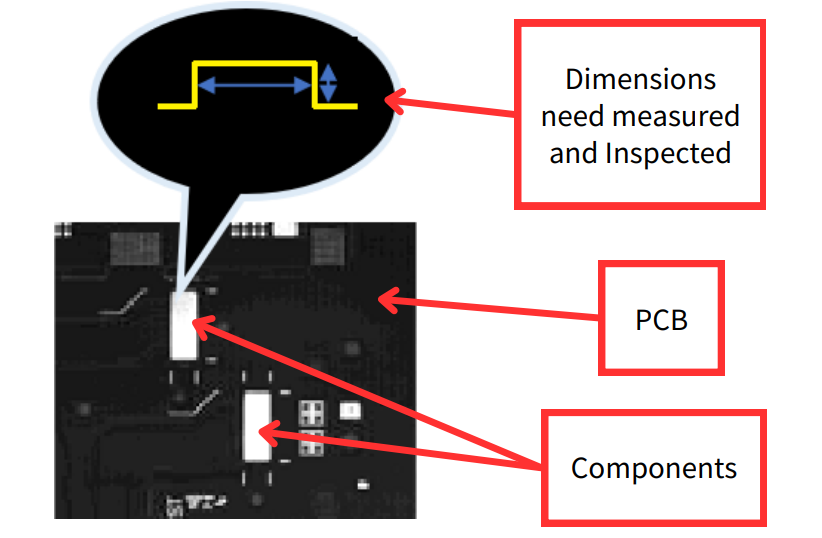

Measure the width and height of the inspection object using a 3D laser scanner.

The thickness of the object to be inspected is 0.2 mm, but since a high-precision 3D laser scanner is used, the Z-axis resolution is 4.4-25.9 μm.

It is possible to detect failures where two parts overlap.

It is also possible to inspect whether parts are in the wrong position.

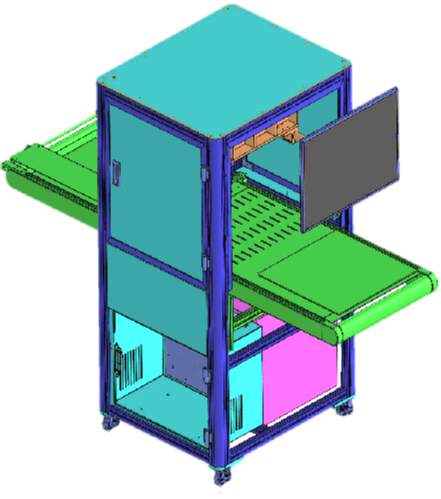

The test results are displayed on the monitor attached to the machine and checked by an inspector.

-

Only one

Only one

-

Hardware

Hardware

-

Software

Software

What is a 3D laser scanner?

3D laser scanners use lasers to measure the distance of objects, allowing for highly accurate and detailed measurements.

3D printers and 3D scanners are often thought of as the same thing, but

3D printers read data and create things,

and 3D scanners read things and convert them into data.

Although they are thought to be similar, this is a device that can do the exact opposite.

This time, we will use it to read the PCB board, convert it to data, and read the dimensions.

Features of Affordable visual inspection camera

SVS2000-M

Features

- PCB board dimensions:

- 400 mm x 600 mm

- One inspection speed:

- 5 seconds / PCB

-

3D head scanner:

- X Resolution: 39.1 – 60.0 μm

- Z resolution: 4.4 – 25.9 μm

- Z repeatability: 1 μm

-

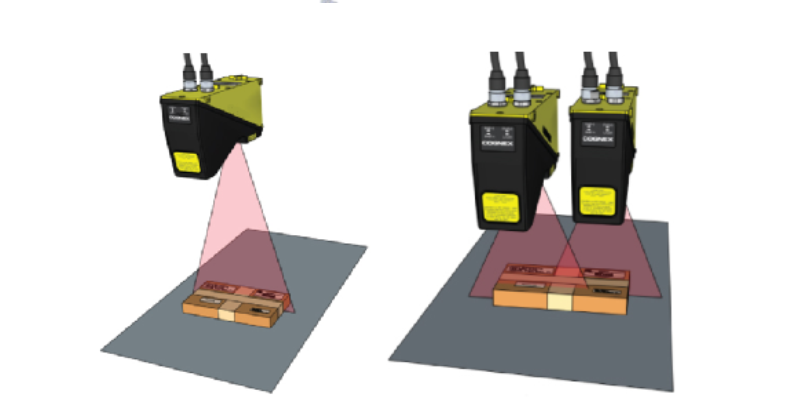

Use one or two 3D laser scanners depending on the size of the PCB board.

Compatible with large PCB boards.

This will inspect the thickness of parts, missing parts, and whether parts are in the wrong position.

By placing the PCB board on the rail, it will automatically flow, and when it enters the inspection area, it will automatically perform the inspection.

The test results will be displayed on the monitor.

Sample collection

conclusion

By using a 3D laser, we were able to measure the width and height of the inspected object.

The test results are displayed on the monitor attached to the machine and checked by an inspector.

How to introduce

-

STEP1

Please contact us by phone or E-mail.

-

STEP2

Evaluation of cameras, lenses, and lighting

Although it can be used with commercially available products, we also individually propose products that suit your company.

Demo version:You can download Demo version from here.

We also send CDs to those who cannot download. (Japan only)

Sample test:We accept sample test for free.

-

STEP3

Introduction

Technical blog

-

2021.06.21

Camera technique in Pattern matching visual inspection software EI710

-

2021.06.21

How to use lighting in Pattern matching visual inspection software EI710

-

2021.06.21

How to use the mirror in Pattern matching visual inspection software EI710

-

2021.06.21

Multiple frame operation function in Pattern matching visual inspection software EI710

-

2021.06.18

Presence / absence inspection of specified color: Concept of color judgment allowable range and tips for setting

-

2021.06.18

3 types of trigger modes in Pattern matching visual inspection software EI710