In this article we would like to introduce an interesting inspection system called “Container Inspection System”! This is a useful system capable of finding defects such as tears, holes, etc. on containers.

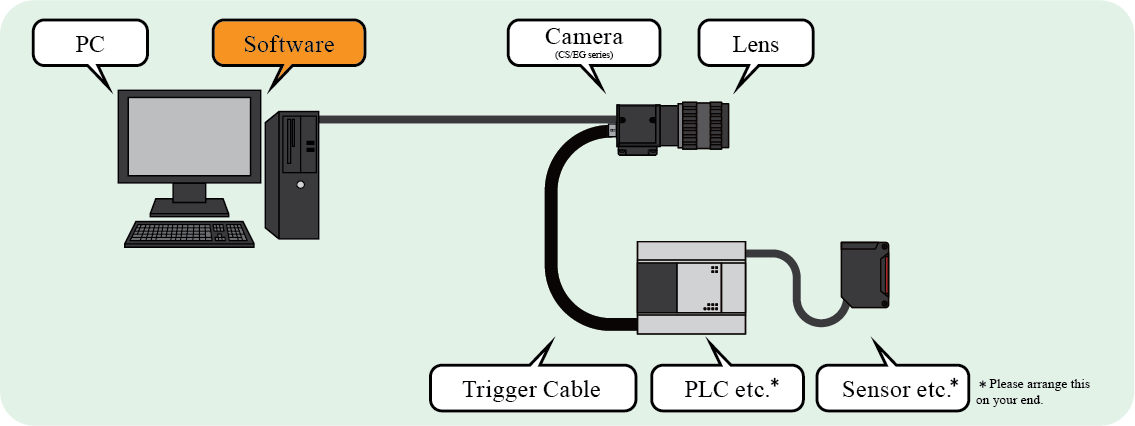

The system specifically focuses on roof surface inspection on containers under 45 feet in size to detect tears, holes, dents, bulges, and dents. They will then look for defects on the surface that are 10 cm or more in length. 3-4 cameras will be set up in the upper position to capture images of the container.

|

|

This camera system can operate outdoors both day and night, and the time for one inspection will be less than 60 seconds. Additionally, it is connected to existing data systems via API.

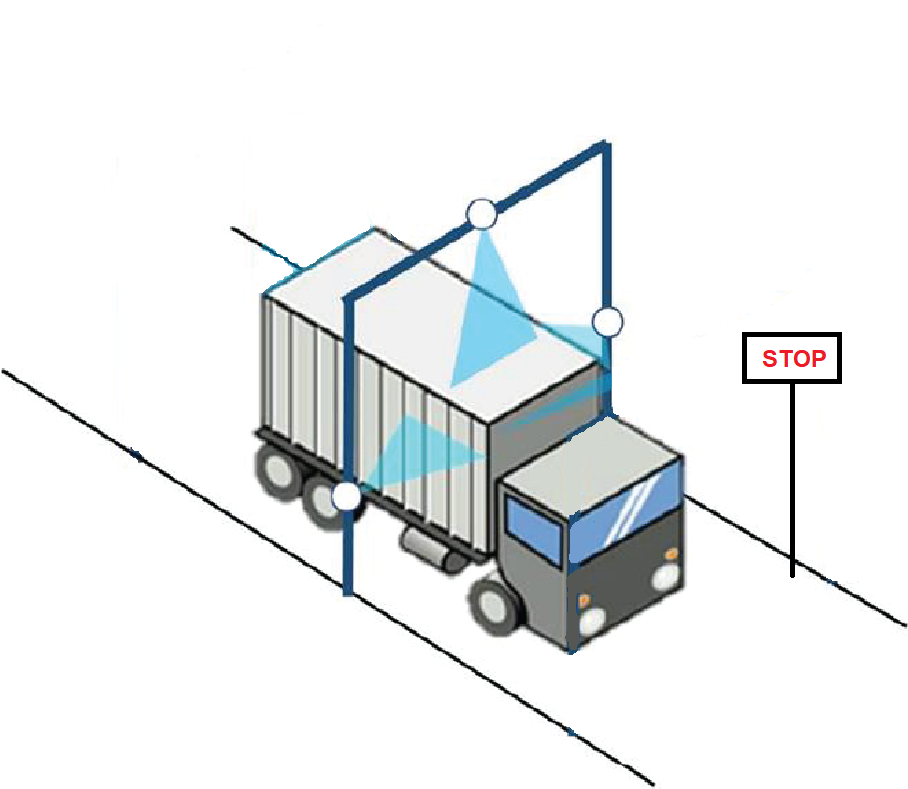

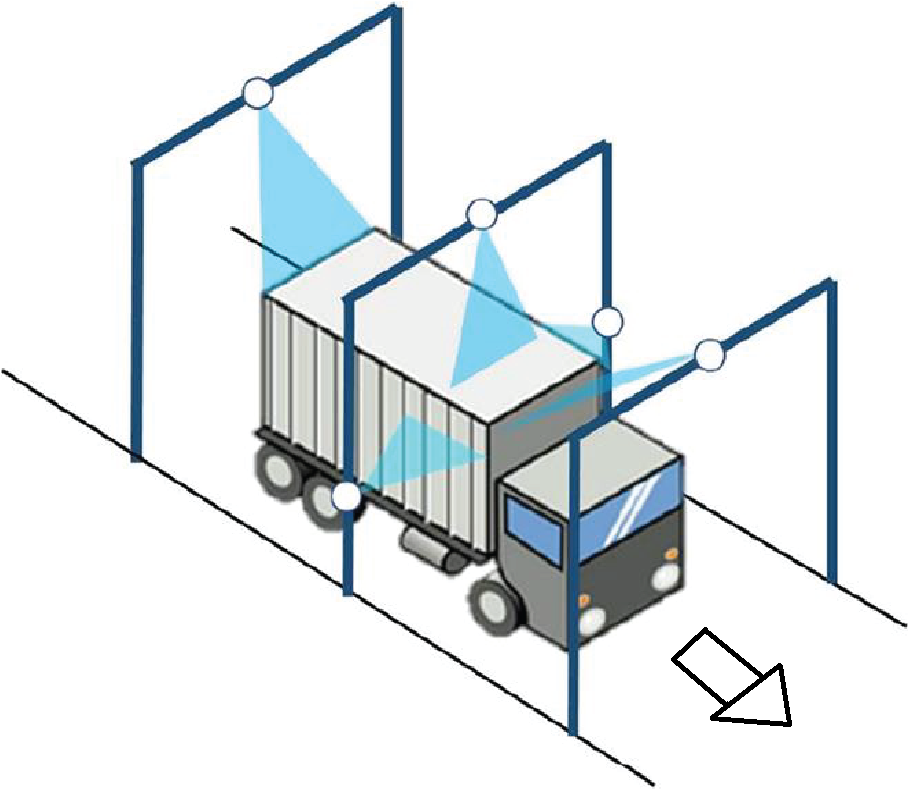

Regarding operation, the system has 2 operating methods as follows. The first is the “fixed photography” method, in which multiple cameras simultaneously take photos when the container stops in a fixed position. The second method is “mobile capture”, which allows photos to be taken while the container is moving. With these two methods, we can check containers anywhere, in any situation.

|

|

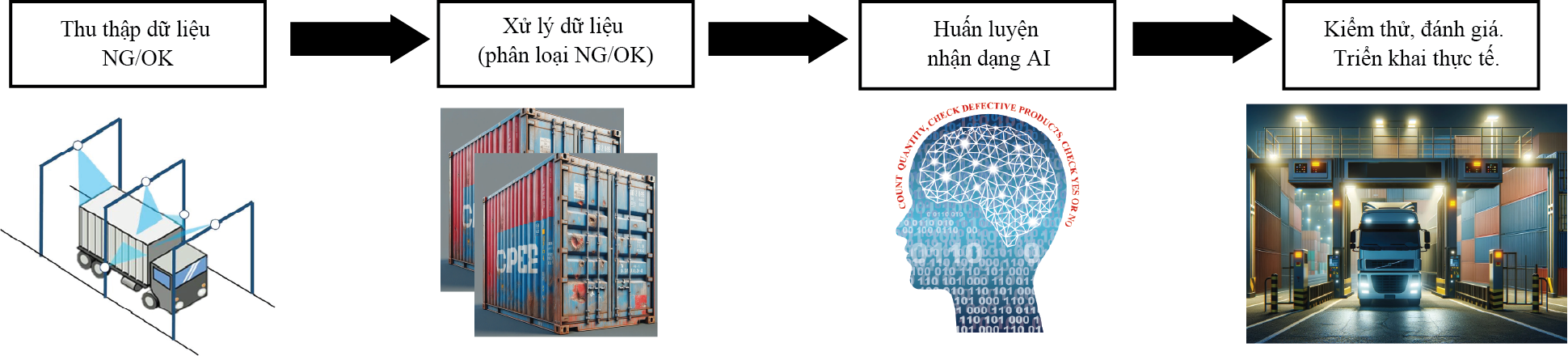

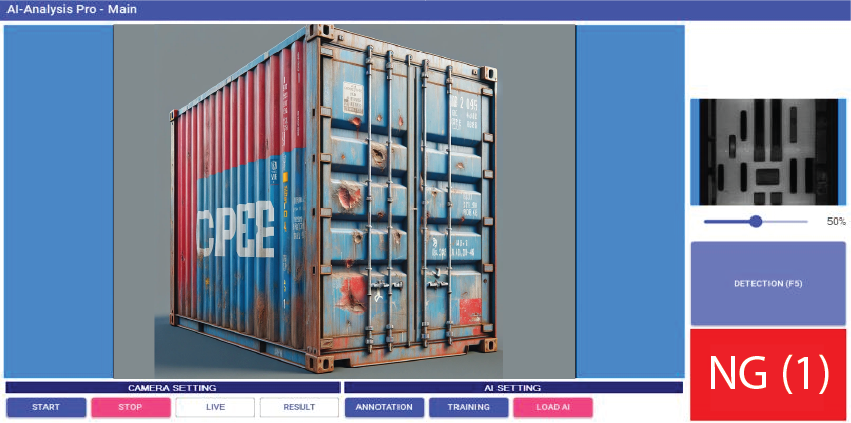

The system will work according to the following process: First the camera will collect OK/NG data. Next is the data processing, NG and OK classification. Then there is the recognition training process for the AI to process the information and determine whether there are errors or not. The final step is evaluation and actual implementation.

The test results will display errors and the number of errors on the screen. This allows workers to react immediately and prepare the container to safely move on to its next journey.

Through this article, it can be seen that the container inspection system brings great efficiency. Just detecting a small error on a container can prevent a major problem from occurring.