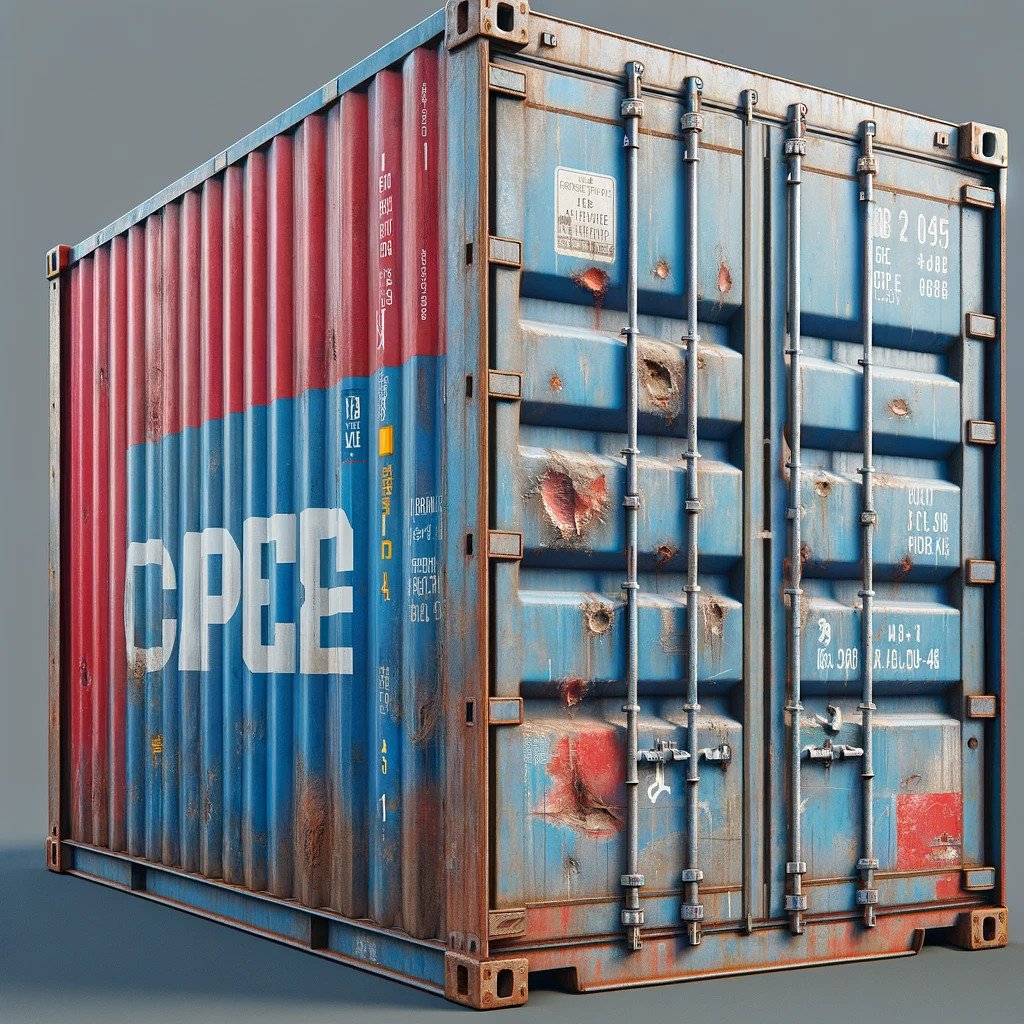

Automatic visual inspection of containers using cameras

Container Inspection System

Product Features

Multiple cameras view the top and side surfaces of the container to detect defects, tears, holes, dents, and expansions larger than 10 cm.

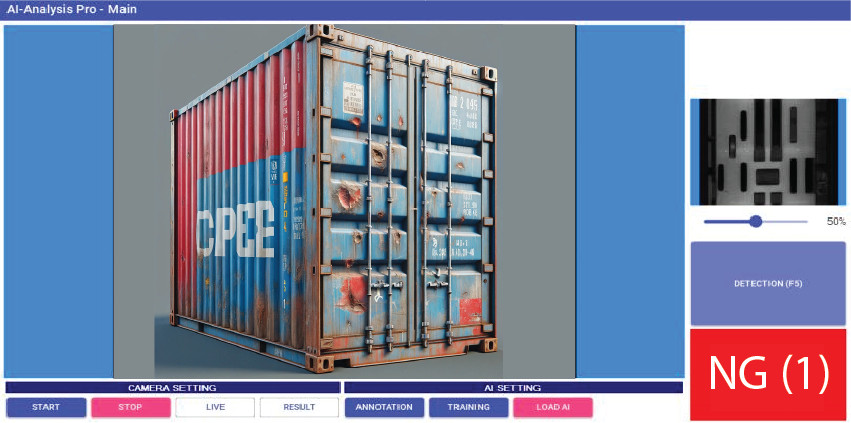

Using AI software, the software remembers various defects, tears, holes, dents, and expansions, and makes decisions using image recognition.

Due to camera resolution issues, detection of defects, tears, holes, dents, and expansions smaller than 10 cm is not stable and is therefore excluded.

AI inspection

AI inspection-

Hardware

Hardware

-

Software

Software

Inspection of containers

-

Inspection Requirements:

Inspect the top and both sides of the container at the same time. Since the inspection target is very large, the field of view that can be seen by the camera is widened, and due to resolution issues, defects, tears, holes, dents, and expansions smaller than 10 cm are not detected.

Move multiple cameras at the same time to inspect multiple locations at the same time.

Outdoor operation is required and detection must be stable in day and night conditions.

The required time for one inspection is 60 seconds or less.

Test results need to be linked with existing data systems.

The brightness conditions are unstable outdoors and during the day and night.

By reducing the camera’s exposure time, suppressing the influence of external light, and emitting strong light, you can shoot under the same conditions regardless of the weather, day or night. -

Solution: Container Inspection System

-

Hardware

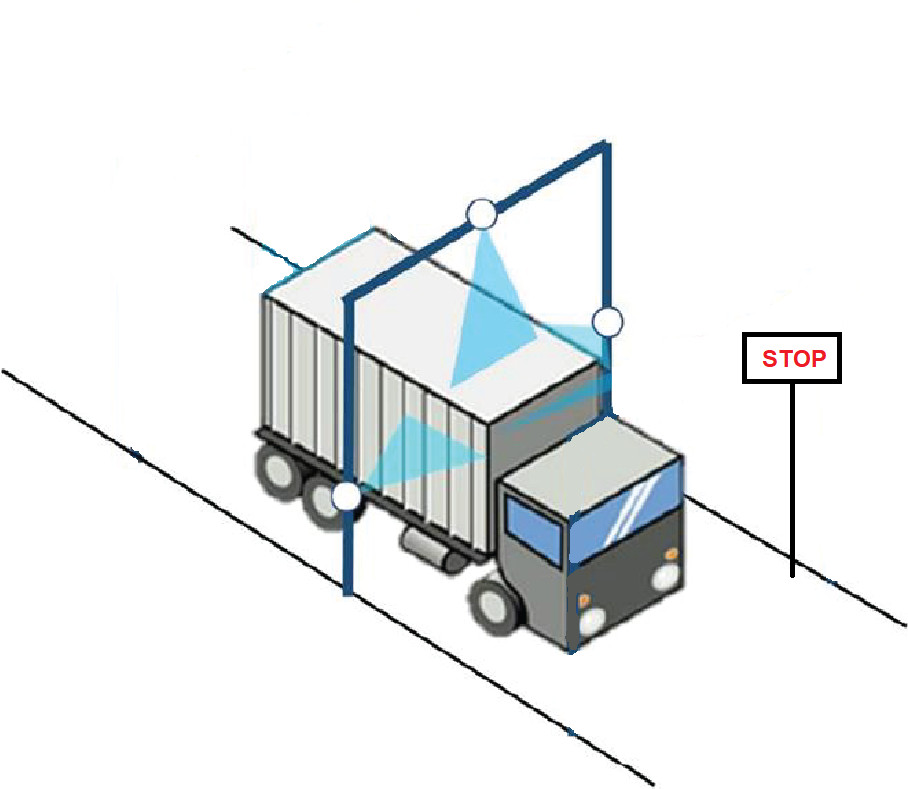

– Install 3-4 cameras on the top of the container. There are two testing methods.

①

The container stops at a fixed position and is inspected using multiple cameras.

The container must be stopped until the test results are available.

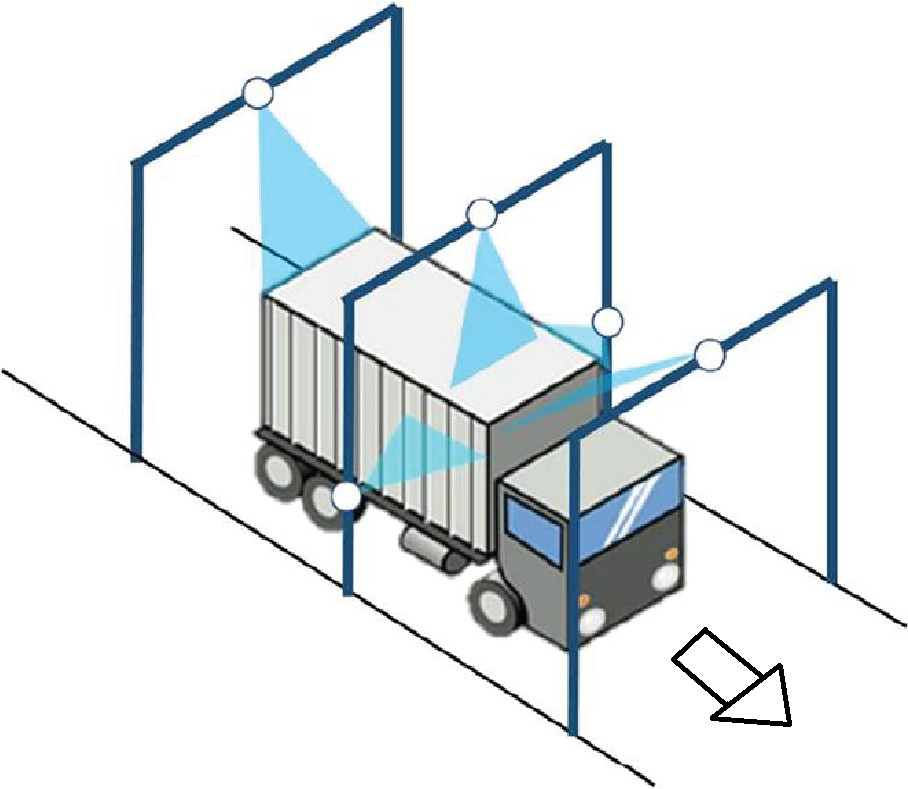

②

The container moves slowly under the camera.

A sensor detects the container and multiple cameras begin inspecting it.

Since the subject is moving even slowly, a global shutter method is required for the camera. -

-

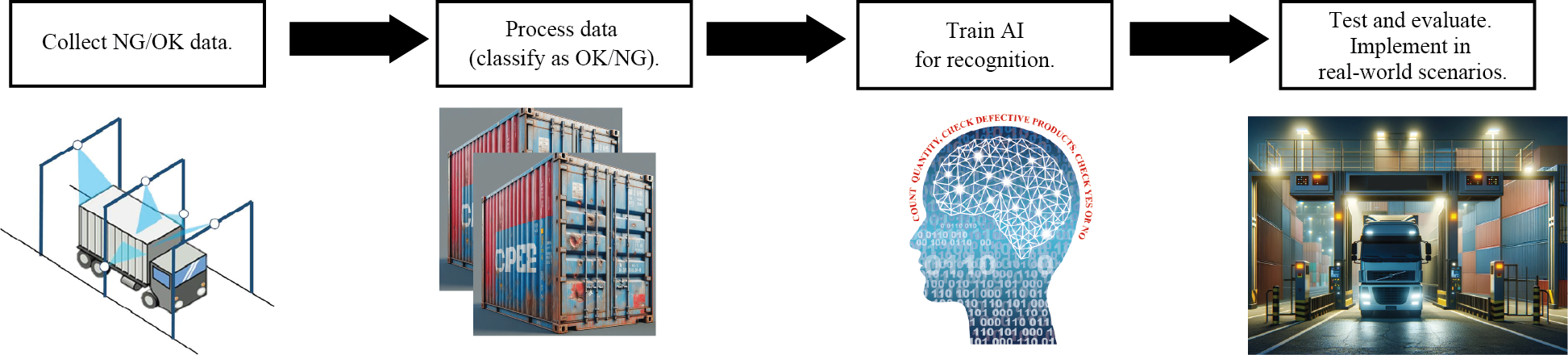

Work flow

Detecting NG requires a large amount of OK/NG data.

First, we will install a camera and acquire a large number of OK/NG images.

Once we have a certain amount of OK/NG data, we use AI software to teach the AI each defect, tear, hole, dent, and expansion.

Once the deep learning is complete, we will begin actual operation.

Since AI is also capable of additional learning, more data can be collected during operation, and more accurate detection can be achieved by performing additional learning.

Test results and Notes

-

Test Result

Container inspection using a camera can detect defects, tears, holes, dents, and expansions of 10 cm or more.

You can also check the results of which NGs were detected on the AI software. -

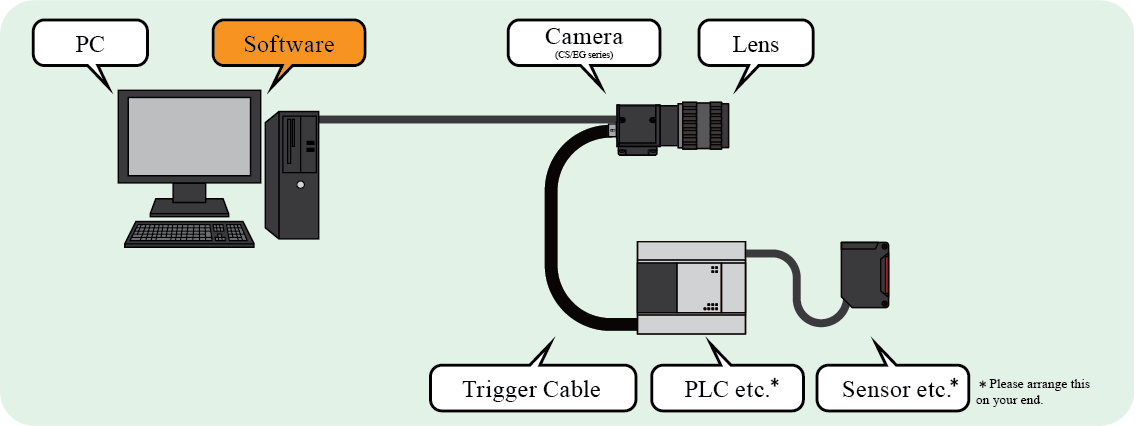

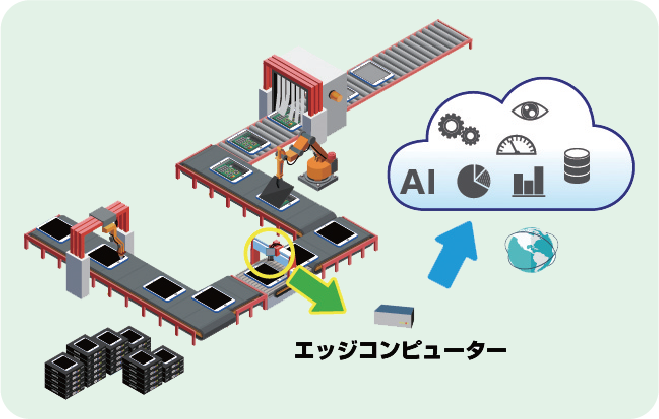

Examples of System Automation

How to introduce

-

STEP1

Please contact us by phone or E-mail.

-

STEP2

Evaluation of cameras, lenses, and lighting

Although it can be used with commercially available products, we also individually propose products that suit your company.

Demo version:You can download Demo version from here.

We also send CDs to those who cannot download. (Japan only)

Sample test:We accept sample test for free.

-

STEP3

Introduction