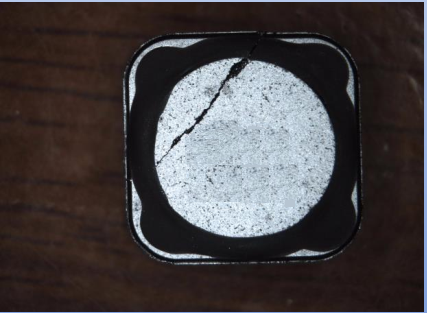

Hello, it’s time for “Innovation Per Week” again this week! Today, we bring you the charm of the crack recognition system, a superb skill that uncovers cracks lurking in your factory. This system is more than just an inspection machine; it’s a remarkable tool that could be dubbed the ‘Crack Detective.’ Let’s delve into the mysteries of this technology!

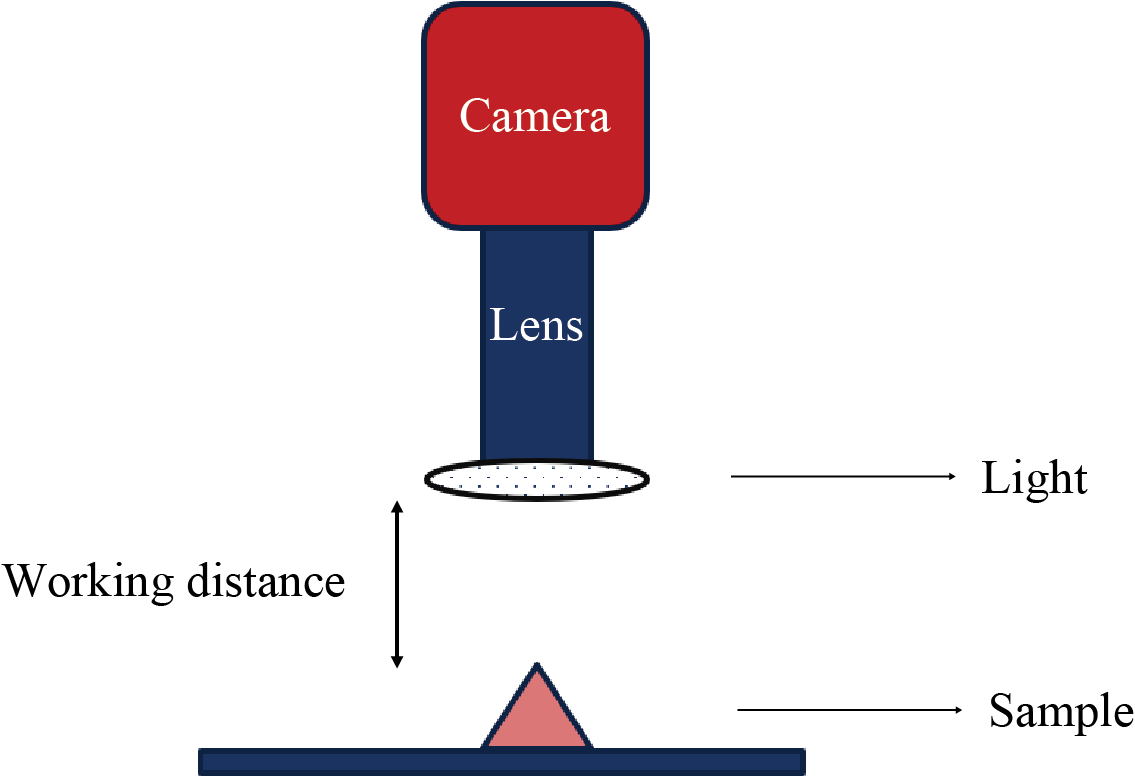

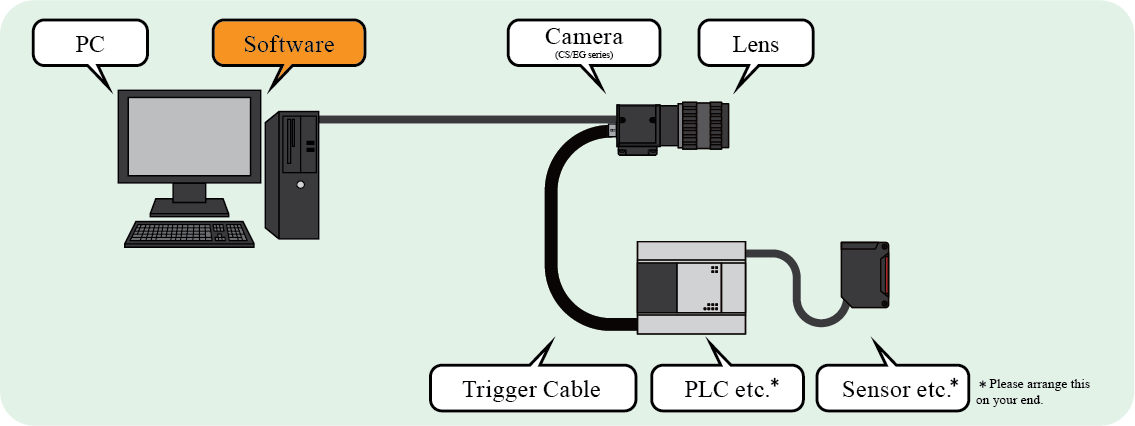

Firstly, this system utilizes a single camera (with 5MP high resolution), an SDS-M-TG-0.5 zoom lens, and a lighting fixture consisting of 81 LED bulbs. This combination ensures that even highly reflective surfaces don’t obscure fine cracks.

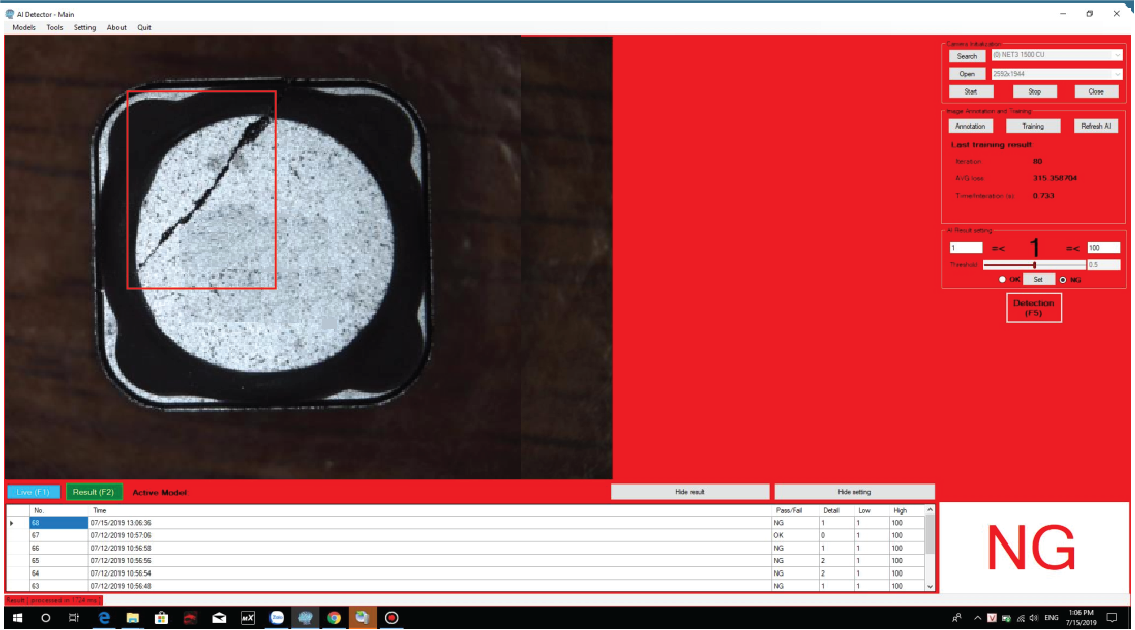

Now, let’s talk about the software. The AI software, known as AI-Detector, plays a role in identifying faulty items and issuing warnings. Setting itself apart from conventional vision systems, this software accurately detects cracks with a 99% precision rate, without confusing them with unrelated issues like scratches or dirt.

The operation is very simple. Take a photo of the sample, transfer it to the PC, and then analyze it using the AI detector to review the results.

What’s particularly convenient is that it doesn’t require a fixed position, allowing inspections from various angles. In cases of unclear cracks, you can even take five more photos to improve accuracy.

This crack recognition system is a technology that seems to have come from the future, but it is here now. No more missing cracks. See you next week at “Innovation Per Week”!

https://www.shodensha.com.vn/visual-inspection/en/crack-detection-system/