Automatic cutting machine that reads location information using a camera

Product Features

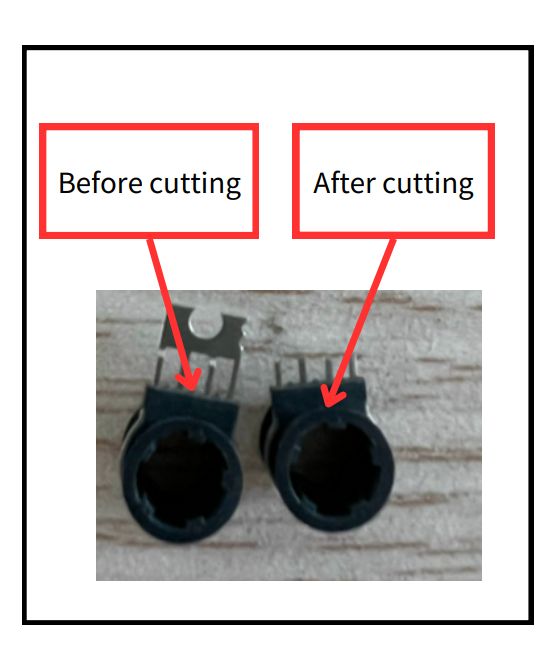

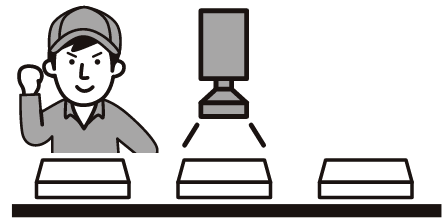

Position with the camera and cut a portion of the connector.

By using a camera to image the excess parts of the connector that inevitably occur during manufacturing, and sending a signal to the cutting machine as to where to cut, it is possible to cut only the excess parts.

Read the product type by reading the barcode and the job on the HMI and change the set dimensions for cutting.

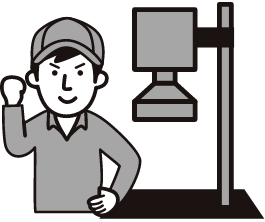

Recording images after the amputation will serve as evidence.

-

Only one

Only one

-

Hardware

Hardware

-

Software

Software

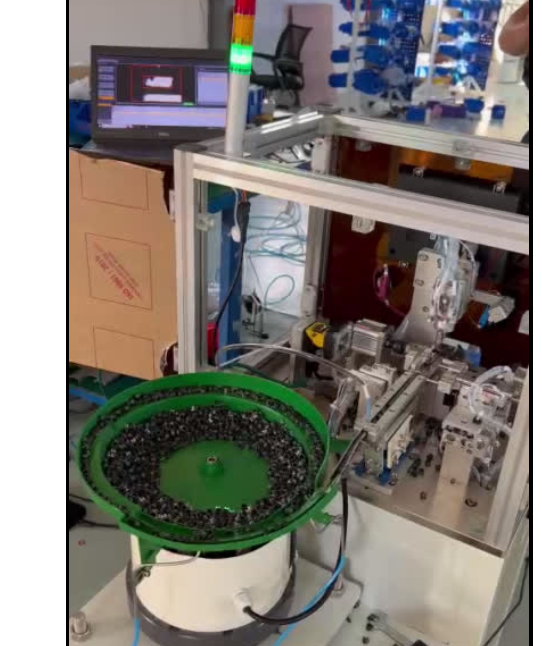

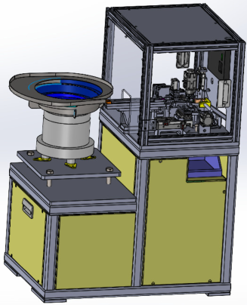

Automatic cutting machine

Features

Inspection

Let AI learn multiple types of connectors.

Read position information from the video of the model trained with each AI.

(The target to be cut must be shown on the camera image.)

After reading the object to be cut with the camera, the position information of the object to be cut is sent to the cutting machine.

The cutting machine moves based on the position information and executes the cutting.

After cutting, the camera saves the cut object as video data again.

Hardware

A desktop computer with a graphics board capable of deep learning

6.0MP GigE Camera

25mm Fixed Focus Lens

Software

AI-Detector

AI-Detector can detect the shape and location information of an object by making it memorize the object.

This time, we will photograph the object to be cut, read the object’s position information (X-axis, Y-axis), and send a signal.

After cutting, a signal is returned from the cutting machine again, and this timing is used as a trigger to save a still image.

Reason for using a camera for positioning

Positioning is generally done using a jig, but it is difficult to use a jig to handle a wide variety of products.

If you use a camera, you can understand the location information by reading the image, so by sending the location information to the cutting machine, you can ensure that the cutting is done according to the cutting location.

How to introduce

-

STEP1

Please contact us by phone or E-mail.

-

STEP2

Evaluation of cameras, lenses, and lighting

Although it can be used with commercially available products, we also individually propose products that suit your company.

Demo version:You can download Demo version from here.

We also send CDs to those who cannot download. (Japan only)

Sample test:We accept sample test for free.

-

STEP3

Introduction

Technical blog

-

2021.06.21

Camera technique in Pattern matching visual inspection software EI710

-

2021.06.21

How to use lighting in Pattern matching visual inspection software EI710

-

2021.06.21

How to use the mirror in Pattern matching visual inspection software EI710

-

2021.06.21

Multiple frame operation function in Pattern matching visual inspection software EI710

-

2021.06.18

Presence / absence inspection of specified color: Concept of color judgment allowable range and tips for setting

-

2021.06.18

3 types of trigger modes in Pattern matching visual inspection software EI710