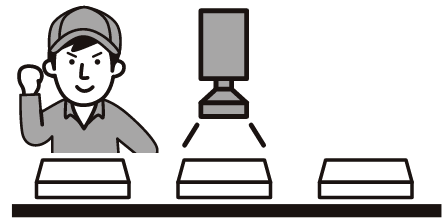

Automatic Visual inspection machine for metal parts

Product Features

Automatic visual inspection system using AI

Determine bending of metal parts and detect presence or absence of scratches

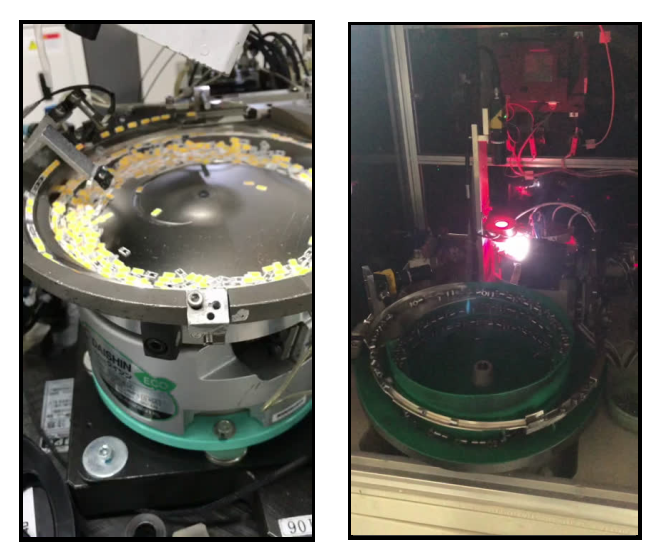

Since it is not possible to detect bends and scratches at the same time with a single camera, we inspect each process separately.

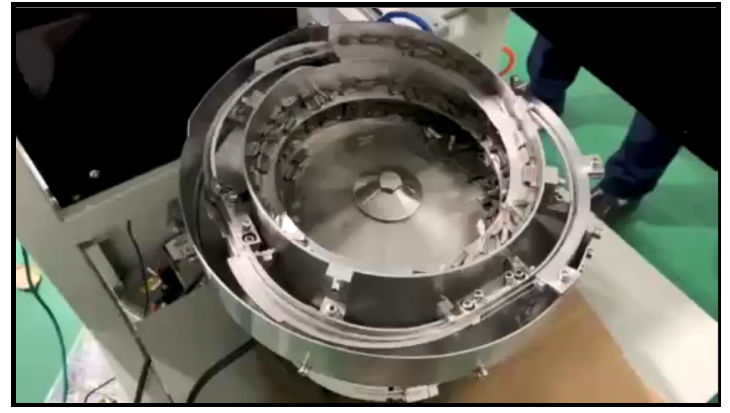

When detecting bends in metal parts, a strong light is irradiated to intentionally generate halation on areas other than the bends, and only the bends are reflected and judged.

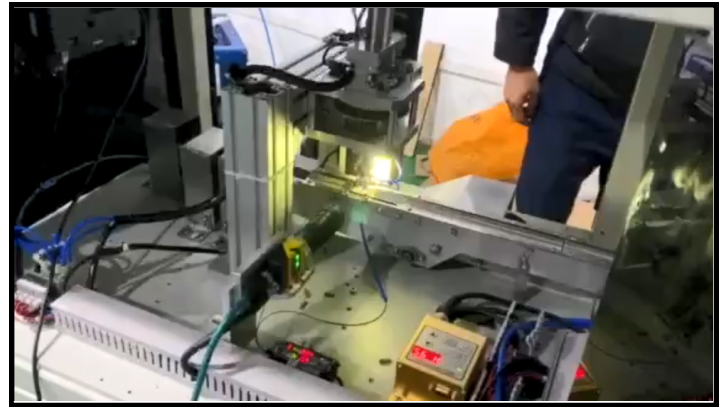

When it comes to detecting scratches, using red lighting makes the scratches stand out, so the idea is to visualize them using red lighting and use AI to detect the scratches.

AI inspection

AI inspection-

Hardware

Hardware

-

Software

Software

What is halation?

Automatic visual inspection system using AI

Determine bending of metal parts and detect presence or absence of scratches

Since it is not possible to detect bends and scratches at the same time with a single camera, we inspect each process separately.

When detecting bends in metal parts, a strong light is irradiated to intentionally generate halation on areas other than the bends, and only the bends are reflected and judged.

When it comes to detecting scratches, using red lighting makes the scratches stand out, so the idea is to visualize them using red lighting and use AI to detect the scratches.

Features Automatic Visual inspection machine

Inspection

Detecting bends in metal parts was unstable and difficult.

Even when using normal lighting, the appearance of the image varies greatly depending on the degree of bending, making it difficult for AI to learn from the image.

By shining a strong light on it, we intentionally created halation, which wiped out all information other than the curve, allowing us to see only the curved part in the image.

If unnecessary information is omitted in this way, it will be easier for AI to learn, and it will be able to detect bends more stably.

When it comes to detecting scratches on metal parts, shining white light on metal tends to cause halation, and once halation occurs, the scratches become invisible.

However, by using red lighting for scratches on metal, the scratched area will appear black, making it easy to see that there is a scratch.

With images like this, it is possible to detect flaws using AI.

Inspection time

Bending detection of metal parts: 1 second

Scratch detection on metal parts: 1 second

How to introduce

-

STEP1

Please contact us by phone or E-mail.

-

STEP2

Evaluation of cameras, lenses, and lighting

Although it can be used with commercially available products, we also individually propose products that suit your company.

Demo version:You can download Demo version from here.

We also send CDs to those who cannot download. (Japan only)

Sample test:We accept sample test for free.

-

STEP3

Introduction

Technical blog

-

2021.06.21

Camera technique in Pattern matching visual inspection software EI710

-

2021.06.21

How to use lighting in Pattern matching visual inspection software EI710

-

2021.06.21

How to use the mirror in Pattern matching visual inspection software EI710

-

2021.06.21

Multiple frame operation function in Pattern matching visual inspection software EI710

-

2021.06.18

Presence / absence inspection of specified color: Concept of color judgment allowable range and tips for setting

-

2021.06.18

3 types of trigger modes in Pattern matching visual inspection software EI710