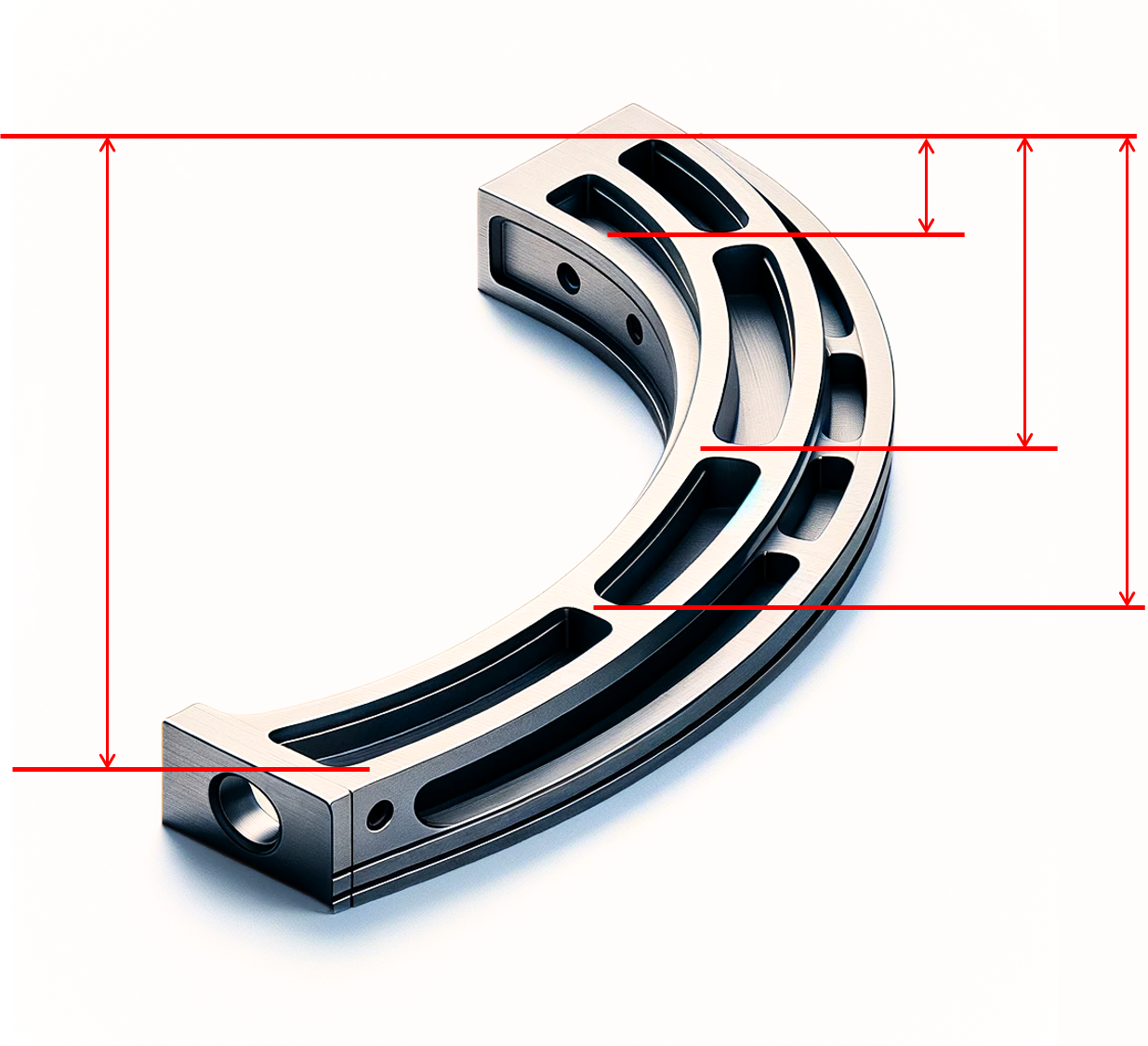

Automatic measurement and inspection system for motorcycle parts

Measurement and inspection system

Product features:

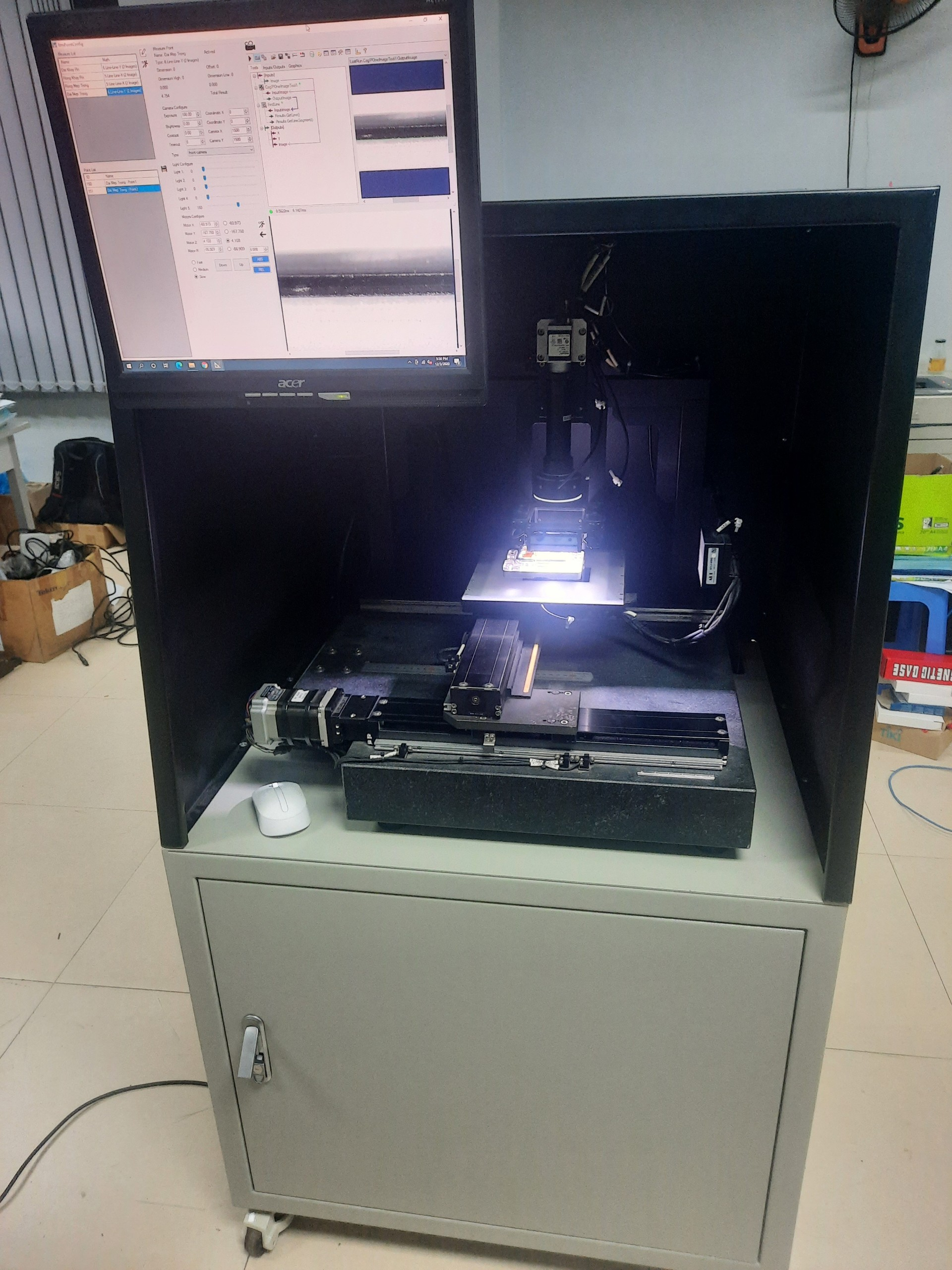

Automatic measurement of multiple locations of special shapes and appearance inspection for scratches, dirt, etc.

It is possible to output automatic measurement results and compare them with the data in the design drawings.

The inspection target is easily affected by light reflection.

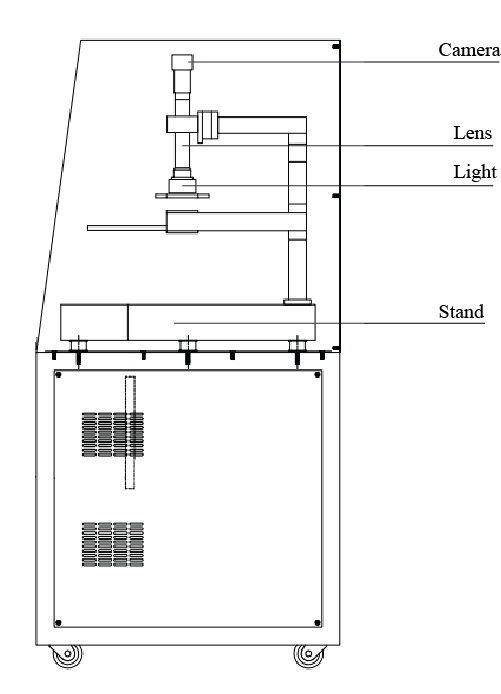

A camera, lens, light, and stand are placed in a box to create a situation where the object is not affected by external light and is inspected.

-

Only one

Only one

-

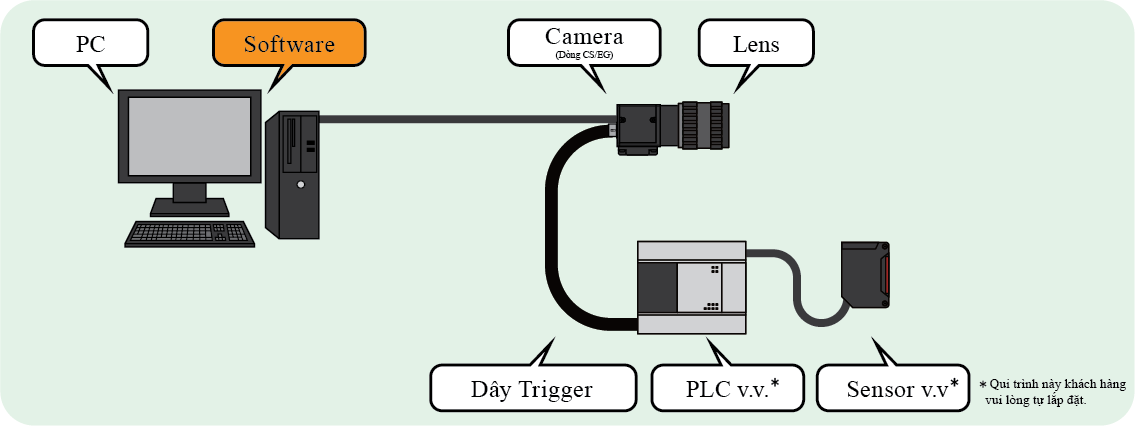

Hardware

Hardware

-

Software

Software

Solutions

Automatic measurement and inspection system

-

Automatic Visual Inspection

Maximum Axis Dimensions (X×Y×Z) 200x200x100 mm Camera 14MP CMOS Sensor Camera Magnification 0,35 ~3,5x Field of View 5 x 5 ~1,33 x 1 External Interfaces USB 2.0/USB 3.0, RS232/RS485 Expected Measurement Machine Dimensions 800x800x1500mm -

-

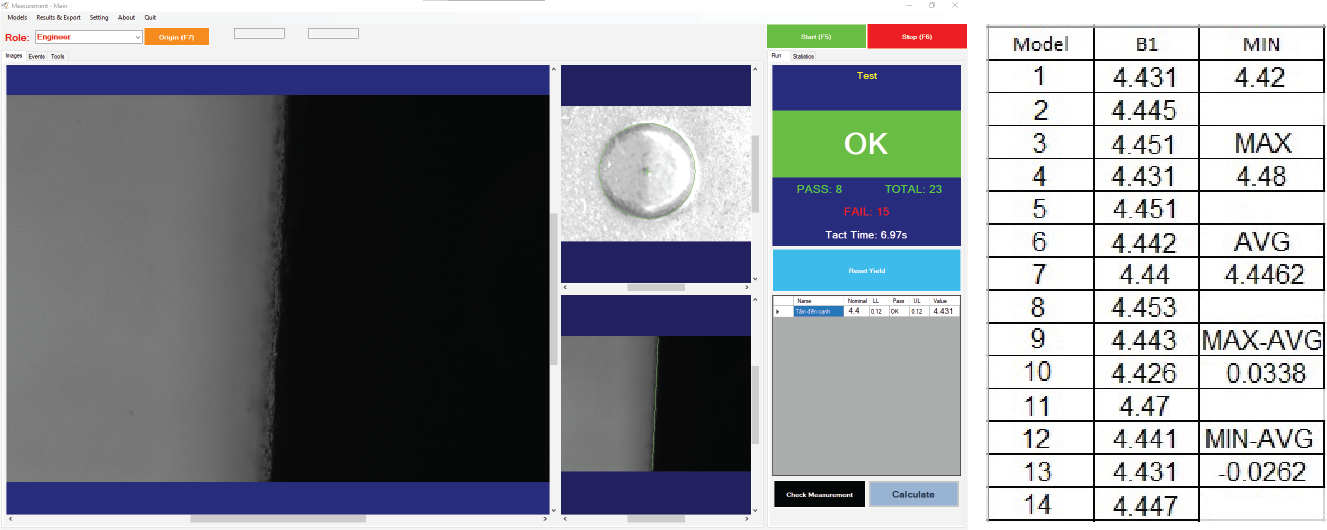

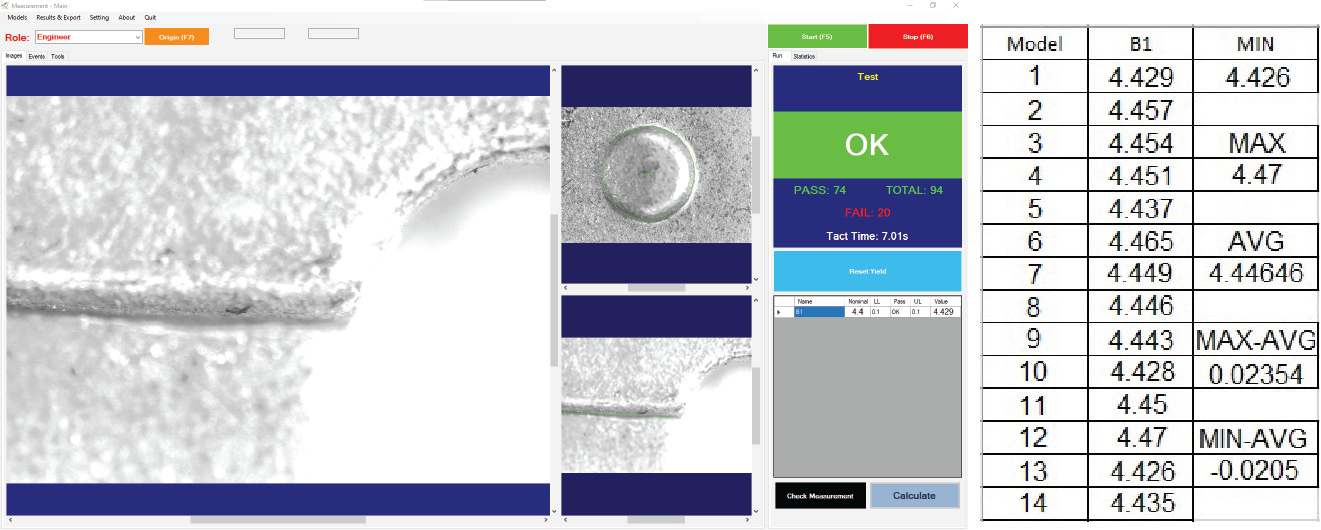

Test results / Implementation effects

-

-

Automatic measurement and visual inspection of specified locations are possible.

Display OK/NG judgment on the screen.

Measured dimensional data is output and can be compared with drawing data.

Implementation effects

1. Labor Cost Reduction:

– Automated data entry and document management significantly reduce manual labor. – Decreasing labor-intensive tasks leads to long-term cost savings. – More efficient processes allow for greater output with fewer employees.

2. Inspection Time Reduction:

– Direct data capture from machines cuts down input time. – Immediate data processing shortens quality control time, preventing production delays.

3. Product Dimension Error Reduction:

– High-precision data acquisition and feedback minimize manufacturing errors. – Ongoing data analysis improves product quality. – Precise data management enhances product accuracy and customer satisfaction, lead to increase efficiency and quality in manufacturing, boost corporate competitiveness.

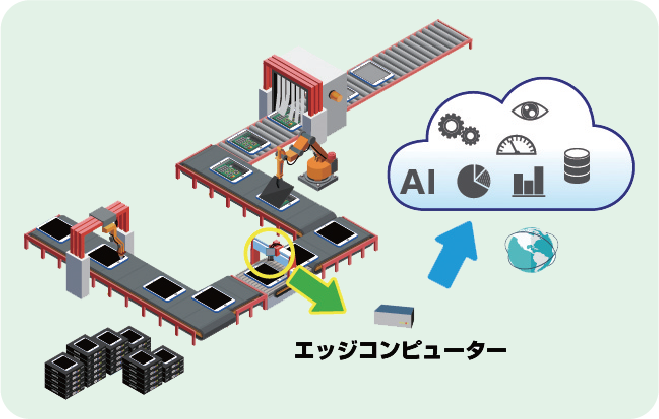

Examples of System Automation

How to introduce

-

STEP1

Please contact us by phone or E-mail.

-

STEP2

Evaluation of cameras, lenses, and lighting

Although it can be used with commercially available products, we also individually propose products that suit your company.

Demo version:You can download Demo version from here.

We also send CDs to those who cannot download. (Japan only)

Sample test:We accept sample test for free.

-

STEP3

Introduction