Isn’t the measuring instrument used for dimensional measurement at the manufacturing site?

Calipers, steel squares, gauges, etc …

Dimensional inspection by humans using such measuring instruments is the mainstream, but it takes time and inspection mistakes due to human errors such as misreading occur.

Therefore, many people want to replace the measuring instrument with an automatic image dimension measuring instrument.

However, there are many types of automatic dimensional measuring instruments in the world, and if you do not select the most suitable one, it may put an extra burden on you.

There are some points to watch out for when replacing a measuring instrument with an automatic image dimension measuring instrument.

Important points for replacement

1.Measurement size

There are many types of automatic dimension measuring instruments in the world, but first of all, the range and size that the automatic dimension measuring instrument can measure are important.

It cannot be measured unless it corresponds to the length you want to measure.

However, this measurement size does affect accuracy.

2.Accuracy

①Lens

The accuracy depends on the size measured by the automatic dimension measuring instrument. In general, the larger the size, the more likely it is to lose accuracy.

The accuracy of this is different because the built-in camera and lens are different depending on the measurement size.

For example, if the measurement is about 150 mm, the lens can incorporate a both sides telecentric lens.

With a telecentric lens, lens distortion is extremely suppressed and you can image as parallel rays.

In addition, there is no dimensional fluctuation of the image within the depth of field (range of focus) of the lens. This lens is ideal for high-precision dimensional measurement.

- Click here for details on telecentric lenses (In Japanese)

High-precision model incorporating botoh sides telecentric lenses - ST1 49.7mm×37.25mm

High-accuracy standard model with both sides telecentric lenses and parallel light lighting - ST2 108mmx80mm

High-accuracy standard model with both sides telecentric lenses and parallel light lighting, wide field of View

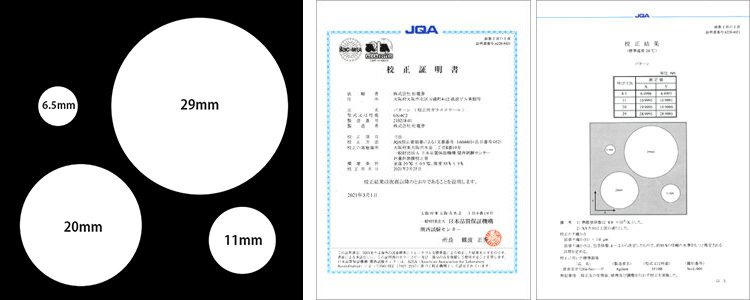

②Calibration scale

A calibration scale is absolutely necessary for measuring the dimensions in the image.

Our ST1 and ST2, which use both sides telecentric lenses, come standard with a calibration lath scale. This calibration glass scale can also obtain a calibration certificate from an external calibration organization.

In addition, the above-mentioned bilateral telecentric lens has a large lens aperture due to its performance. The wider the size that can be imaged, the thicker and heavier the lens itself, and of course the higher the price.

Therefore, it is not realistic to incorporate a both sides telecentric lens for dimensional measurement of about 150 mm or more.

We also have a Wide model that can measure dimensions up to 360 mm and a Long model that can measure dimensions up to 1 m, but both sides telecentric lenses cannot be incorporated into these.

Instead, it is supported by a 20.0 megapixel high-pixel camera and a 20.0 megapixel fixed-focus lens.

This fixed-focus lens is different from the both sides telecentric lens mentioned earlier, and the magnification (dimensions) varies depending on the shooting distance, and the lens also has lens distortion. This lens is not suitable for high-precision dimensional measurement because it has so-called dimensional fluctuations and the image distortion caused by the lens is large.

We are improving the accuracy by the following measures.

Wide model that can measure dimensions up to 360 mm

- Wide 360mm×360mm

A model that can measure dimensions even in a three-dimensional shape with lens distortion correction and height calibration

- Lens distortion correction Use a metal plate and perform software processing.

→Image processing of lens distortion correction with software is supported.

- Software processing is performed using 5 types of stainless steel blocks for dimensional calibration with different heights.

→It is possible to deal with size fluctuations due to shooting distance by calibrating the dimensions for each height difference.

Long model that can measure dimensions up to 1m

- Long 1,000mmx750mm

Square, rectangular thin sheet-like vertical and horizontal dimension measurement model

- The work target that can be measured is limited to a sheet of thin material (paper, resin, metal plate, etc.).

→By keeping the shooting distance constant, the magnification (dimensions) does not change.

- Limited to vertical and horizontal dimensional measurements at specific locations.

→By limiting to a specific location, the dimensions are calibrated at that specific location to deal with lens distortion.

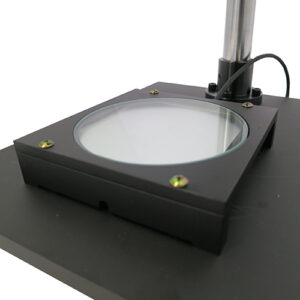

②Light

Lighting also greatly affects accuracy. For high accuracy measurement, it is best to measure with a shadow like a projector. Therefore, it is necessary to measure the external dimensions.

The lighting at this time is a transmitted lighting (backlight) type, but it is often a diffused light type. This diffused light is not suitable for this highly accurate measurement.

Diffuse light is also emitted in the diagonal direction. In this case, even if the lens attached to the camera is constructed so that parallel light is captured by the camera with both sides telecentric lenses, it is meaningless if the light source side diffuses and irradiates the light diagonally. It means that the light irradiation direction of the light source is not parallel rays.

In addition, there is a high possibility that light will rewind on the front side of the sample, making it difficult to remove edge boundaries. You can see that the accuracy will drop if the edge boundaries are not clear.

In order to make this transmitted illumination a parallel ray, a both sides telecentric lens is also installed on the illumination (light source) side. This means that one automatic dimensional measuring instrument will have two expensive both sides telecentric lenses, and the price will jump at once. This is one of the reasons why automatic dimension measuring machine (system) are expensive.

We have developed a parallel ray type transmitted illumination that does not use a both

sides telecentric lens, and by incorporating it, we have created a low-cost automatic image dimension measuring machine (system).

Its price is 1/4 lower than that of other companies, and it is an automatic image dimension measuring machine (system).

High-accuracy model incorporating parallel light transmission illumination

- ST1 49.7mm×37.25mm

High-accuracy standard model with both sides telecentric lenses and parallel light lighting - ST2 108mmx80mm

High-accuracy standard model with both sides telecentric lenses and parallel light lighting, wide field of View

③Level of automatic image dimension measuring instrument

The levelness of automatic image dimensioning affects accuracy. As mentioned above, even if you measure with parallel rays, the accuracy will drop if the measuring instrument itself is not horizontal.

Also, the sample itself must be placed horizontally.

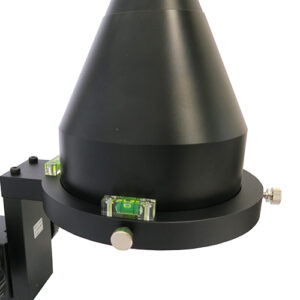

All of our automatic image dimension measuring instruments are equipped with a spirit level as standard equipment, and you can check the levelness of the measuring instrument and the degree of horizontality of the camera angle, and you can level it according to the situation of the customer’s measurement site

In particular, the Wide type and Long type are equipped with a goniometer for adjusting the camera angle and levelness as standard equipment.

- ST1,ST2の水平器

- Wide,Longの水平器

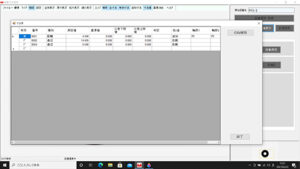

3.Software

When measuring in the image, the software automatically measures it, but the usability of this software is also an important selection point.

Our automatic image dimensional measurement software isSuper simple!

- Place the sample and get the edge with one click.

- Register the product type by specifying or adding an arbitrary measurement point.

- All you have to do is replace the sample, measure the product type, and replace the sample only.

Other useful functions

- No alignment required

The measurement automatically recognizes the position of the object and automatically measures the dimensions. Also supports rotation

- Easy data storage

Measured values can be saved in Excel data format. You can also save still images.

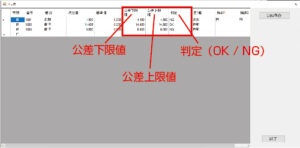

- OK / NG judgment

OK / NG judgment can be made by setting the lower limit of tolerance and the upper limit of tolerance.

The value that was NG can be displayed by changing the color in the image.

- Pinpoint digital zoom function

By turning the mouse wheel, it is possible to zoom in with the digital zoom centering on the point indicated by the mouse cursor when clicking the measurement point.

Summary

Nowadays, dimensional measurement in images is progressing, and it has become possible to realize dimensional measurement efficiently and without human error.

This time, we introduced some points for selecting an automatic image dimension measuring instrument.

It is important to select the type that suits the purpose.

As mentioned above, it is necessary to select various parts in order to perform automatic image dimension measurement.

Optical knowledge and know-how are indispensable for this selection, and it is also necessary to consider the balance between each part.

However, all of our automatic image measuring instruments are set in the system contents.

Of course, the system configuration is based on the combination balance of each part.

We have a demo machine, so please evaluate it by actually renting it out.

- ST1 49.7mm×37.25mm

High-accuracy standard model with both sides telecentric lenses and parallel light lighting - ST2 108mmx80mm

High-accuracy standard model with both sides telecentric lenses and parallel light lighting, wide field of View - Wide 360mm×360mm

A model that can measure dimensions even in a three-dimensional shape with lens distortion correction and height calibration - Long 1,000mmx750mm

Square, rectangular thin sheet-like vertical and horizontal dimension measurement model

In addition to the above, measurement speed, storage location, etc. are also important points, but that will be another opportunity.