A completely new automatatic visual inspection package software with unique algorithms

●A completely new appearance inspection software that looks like AI, but isn’t.

●After registering at least 10 images of good products, you can start inspection right away!

●If an overdetection occurs, you can register it right away!

●Differences from good products are detected as deformations in the shape and differences in vectors!

*The camera is compatible with the CS series.

*We recommend using cameras with a global shutter.

New visual inspection algorithm

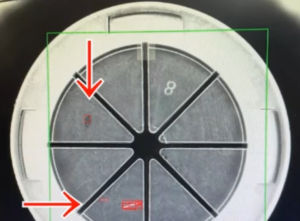

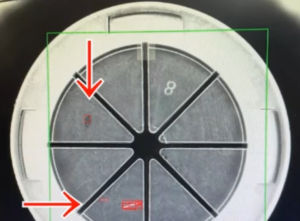

Going beyond just brightness, it is now possible to detect the difference between a good product and a defective product by looking at the shape and vector differences!

|

|

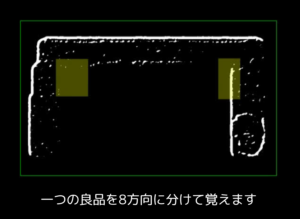

| Good product image |

NG detection image |

When inspecting the above objects, detection is unstable due to the balance of light when using conventional rule-based systems.

However, by using the CG method (cross grid method), stable detection is possible by simply memorizing several dozen images of good products.

There is no need for the huge amount of training data and long learning times required for conventional AI systems.

Strengths of the CG method (cross grid method)

|

|

|

|

Like AI

You can start by registering 10 or more good production images.

|

But it isn’t AI

No need for a high spec PC, and learning time is just a few minutes

|

New inspection technology

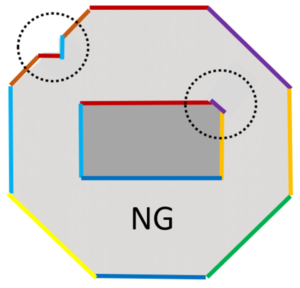

Especially excellent for detecting small scratches and dents that occur on the edges of workpieces

|

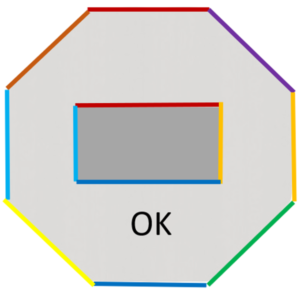

Inspection algorithm concept

The CG method (cross grid method) registers a good product, memorizes the shape of the image of the good product, and compares the position and direction of each edge that makes up the contour.

This makes it possible to detect vectors that are not present in the good product.

Frequently asked questions about automatic visual inspection

Example of an answer using the CG method (cross grid method)

Q:What is the detection accuracy?

A:

A:Events can be detected from as little as 3 pixels, so even subtle changes may be detectable.

Q:What about the stability and reproducibility of the test?

A:

A:Even if there are lighting conditions or individual differences, it remains relatively stable because it looks at vectors.

Q:Is it easy to learn and set up?

A:

A:It’s very easy; just take several dozen photos of good quality products and press the learning button.

Q:How long does one inspection take?

A:

A:It depends on the resolution of the camera used, but it is generally within 0.5 seconds.

Q:What kind of tests is it effective for?

A:

A:It is suitable for detecting defects that occur in finished products with a fixed shape.

As the inspection involves memorizing the shape, it is not good at detecting objects with irregular shapes or with varying positions and orientations.

Q:Can it be linked to other systems?

A:

A:Since I/O control is possible, it is possible to start inspection and output OK/NG inspection results.

Automatic visual inspection: 3 easy steps to implementation

No need to know anything about image processing!

●Step 1: Interview and sample confirmation of test subjects

We ask you “What kind of products do you want to inspect and how?” and propose the optimal inspection method based on the samples.

For example, check for scratches, labels, chips, etc.

Please provide us with photos and samples of the object to be inspected and the shape of the workpiece.

●Step 2: Propose the optimal system configuration and lend a demo unit

We will propose a system that combines lighting, cameras, and appearance inspection software based on the samples we receive, and you can use the actual demo unit to check the detection accuracy, etc.

Select lighting and lenses to suit your workpiece

Explaining how to use visual inspection software

●Step 3: Introduction

The operation is simple and it can be used immediately in the field.

Support for registering test items and setting judgment criteria via telephone, web meeting, etc.

Support for registering test items and setting judgment criteria via telephone, web meeting, etc.

Operating environment

- USB camera: DirectShow compatible camera (color camera required)

(Video format: RGB24 YUY2 Resolution: 640X480 compatible)

- WindowsXP, Vista, 7, 8, 8.1, 10, 11 (DirectX 9 or higher must be installed)

*The required PC specifications vary depending on the number of cameras and the number of pixels used. Please contact us for details.

For example, check for scratches, labels, chips, etc.

For example, check for scratches, labels, chips, etc.