・What is welding?

Welding is “joining two metal base materials together using heat or pressure.”

Or “joining by adding filler metal and using heat or pressure.”

The main methods used are heating with electricity, arc discharge, gas, plasma, laser, etc.

At this time, the length of the weld leg (bead) formed at the weld (weld overlay) has a large effect on the strength of the weld joint.

-

Welding evaluation

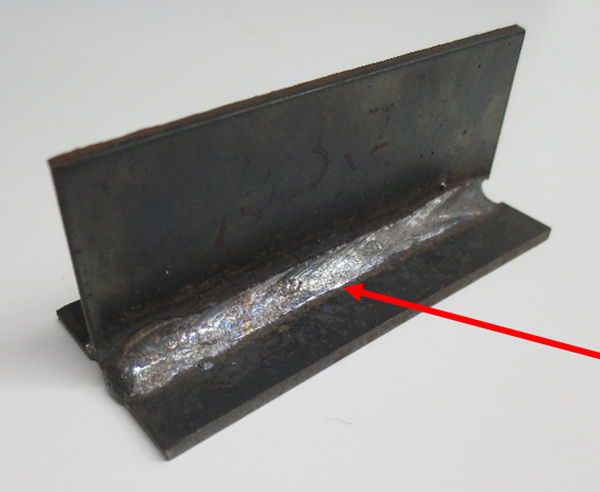

The part with the red arrow in the image is the weld bead.

The external shape and dimensions (width, length, height) of this weld bead vary depending on the welding conditions.

Depending on the shape of the weld bead, it is possible to evaluate whether proper welding was achieved and whether there are any welding defects.

There are following types of welding defects:

・Insufficient surplus

·Overlap

·undercut

·pit

・Crack etc.

To evaluate this weld bead, it is necessary to measure its three-dimensional shape.

・What is inspection in welding?

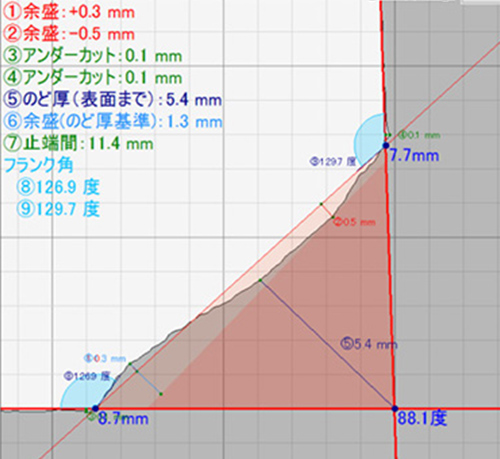

The dimensions specified in the cross section of the weld are the “throat thickness,” which is the minimum thickness of the weld bead, and the “penetration amount” and “penetration depth,” which are the length from the molten peak of the metal base metal to the metal base metal surface. etc. are stipulated.

⇒Click here for information on welding penetration measurement

Dimension regulations include the minimum length from the weld root, which is the base of the joint, to the toe of the weld bead, “leg length.”

This leg length is one of the criteria for determining the optimal bead width.

・Improved efficiency in measuring the shape and length of weld leg length (bead)

Bead inspection is required to ensure welding quality.

The common testing methods are:

・Visual comparison with good product samples

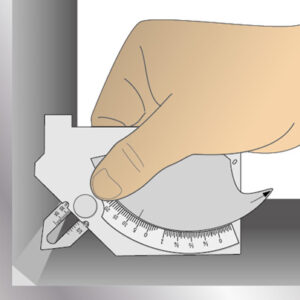

・Method of visually comparing with welding gauge

However, these require a high level of skill and time from the person in charge of the inspection, and judgments vary depending on the person.

Additionally, the welding-specific gauge measurement method requires measurements at multiple locations, which is inefficient.

<Image of welding gauge measurement>

By using the products below, you can solve these weld bead measurement problems.

・Recommended products for measuring weld leg length (beat)

This product is a 3D handy scanner that can instantly measure the cross section of a weld bead in a non-contact, non-destructive manner by simply shining a laser on the weld area you want to measure.

* Penetration inside the weld and blowhole inside the weld cannot be measured.

Non-contact optical cutting method that operates a trigger switch eliminates the need for measuring with a straight scale or welding gauge.

The laser irradiation line applied to the weld can be 3D scanned to measure the 3D shape with high precision and display a cross-sectional view.

Therefore, there is no human error or variation, and weld bead (leg length) can be measured instantly and non-destructively.

~Features of this device~

Feature 1: Handy type and easy to use 3D handy scanner

・Simply connect to your computer or tablet via USB. You can immediately operate the welding measurement software built into the main unit by installing it on your PC.

– It is a handy type, so it is easy to handle, and can measure large and heavy objects that were previously difficult to measure, even in small spaces.

Feature 2: Measure by simply holding it over the location you want to measure and pulling the trigger away.

– When measuring a weld bead, conventional methods require measuring with calipers or a dedicated welding gauge, but with this device, pinpoint measurement is possible with a single laser irradiation.

– Measurements can be taken by simply holding it over the welding bead (the raised welding mark) and operating the trigger switch.

– Comes with a removable guide rod that is convenient until you get used to measuring distances and angles.

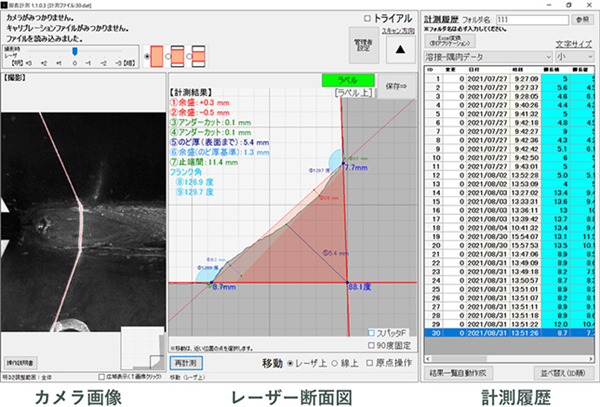

・12 points such as the “leg length”, “undercut”, “joint angle”, and “retention” of the weld bead can be easily measured in 3D using the optical cutting method.

Feature 3: Instantly display and save leg length measurement results on your PC screen

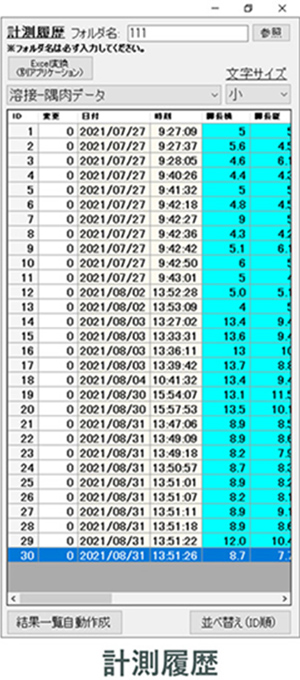

-Measurement results can be saved as a file and the data can be used in Excel®.

The numerical value is displayed at the same time as the measurement, allowing for accurate recording without mistakes.

This eliminates the need for handwritten records, which can lead to errors, and is also effective in preventing falsification.

・Traceability can also be ensured.

~ Even more convenient features ~

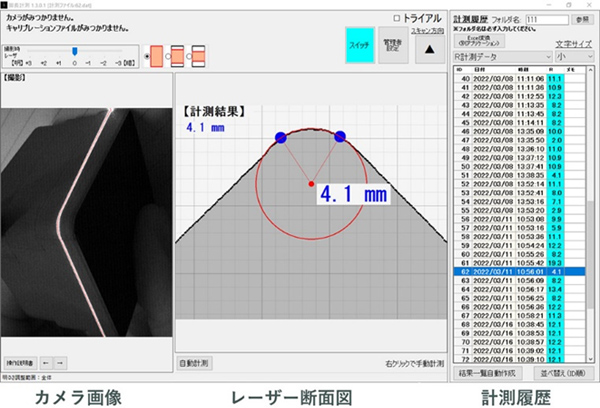

・Đo góc R (radius)

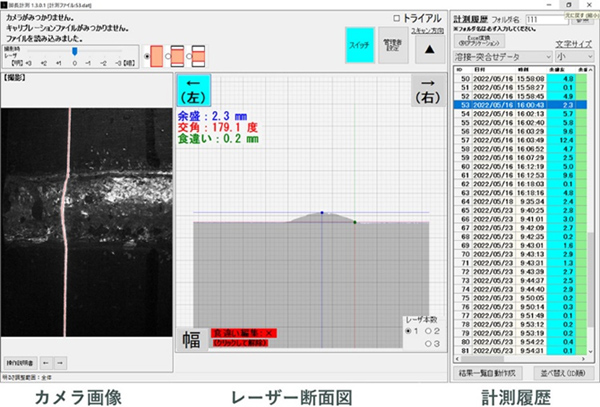

・Tính năng đo lường cho việc kiểm tra mối hàn ép (đối mặt)

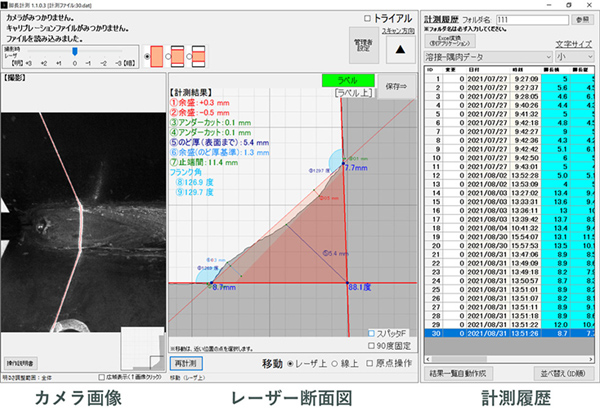

Function 2: Display camera image, laser cross-sectional view, and measurement results on one screen

-

・Camera image

Display the image of the part captured by the camera・Laser cross section

Display measurement results in an easy-to-understand manner with numerical values and cross-sectional diagrams・Measurement history

Display the numerical value of the measurement result

Function 3: Measurement history can be output to Excel®

Function 4: Read QR code

By reading QR codes and barcodes, you can easily link items to be measured and manage measurement results with QR codes.

In addition, by combining QR codes and the cloud, it is possible to visualize and DX the welding work.

Summary

If you want to dramatically improve and streamline weld bead shape measurement, which is difficult to measure accurately,

[Welding leg length handy 3D scanner CSM-HS10WL] is very convenient.

・Eliminates the variation in measurement values caused by people and realizes quantitative measurements.

・You can also read QR codes and link them with product data.

– Accurate 3D shape of objects can be measured instantly without contact.

・It is possible to visualize abnormal parts of the weld bead using a color map.

“Welding leg length handy 3D scanner” is available at our company.

For more information, please see the product page below.