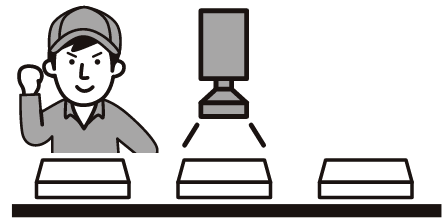

Position detection and counting system

Position detection and counting system

Product Features

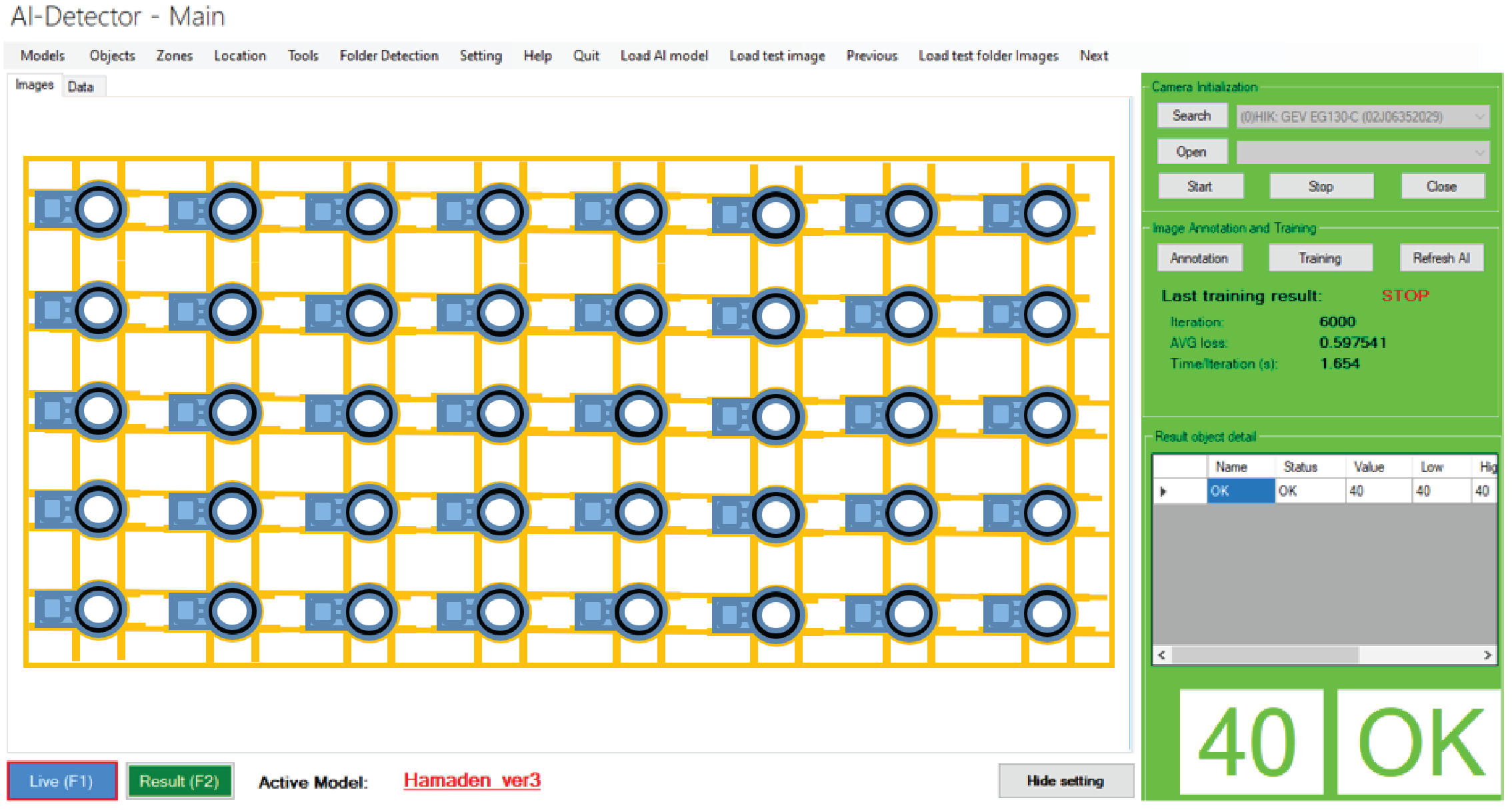

It is possible to count the number of products and decide whether it is OK or not based on the count.

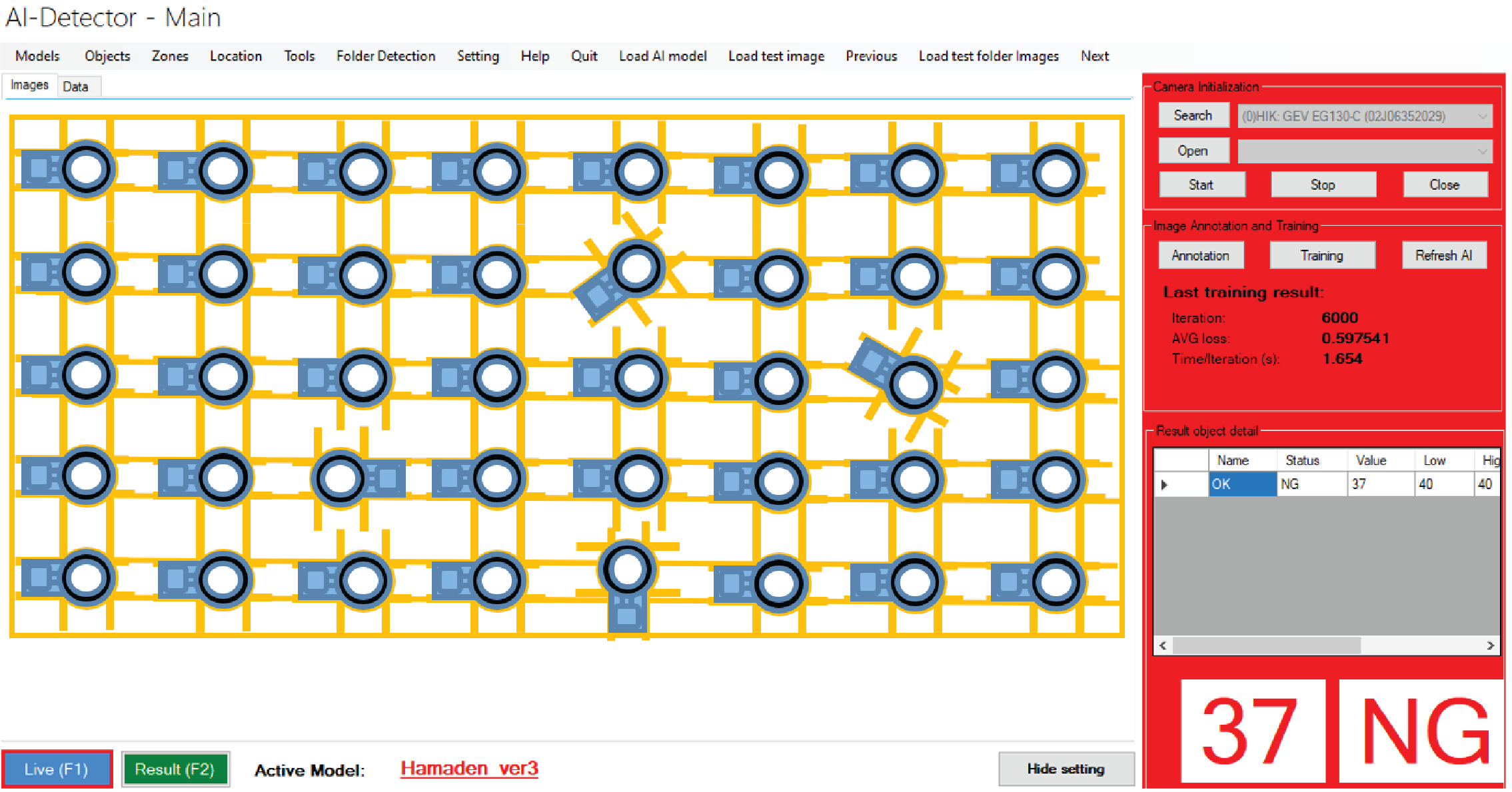

If products that do not suit the standards are mixed in, it is also possible to judge the product as NG.

The inspection can be performed in about 1 second each time to detect the position and determine whether the count is OK or NG.

-

Only one

Only one

-

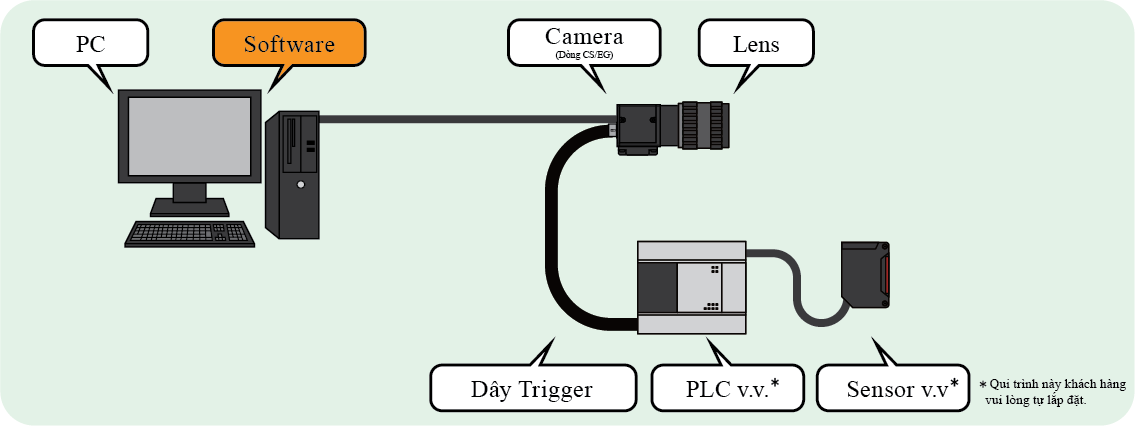

Hardware

Hardware

-

Software

Software

Inspection : Position detection and counting system

-

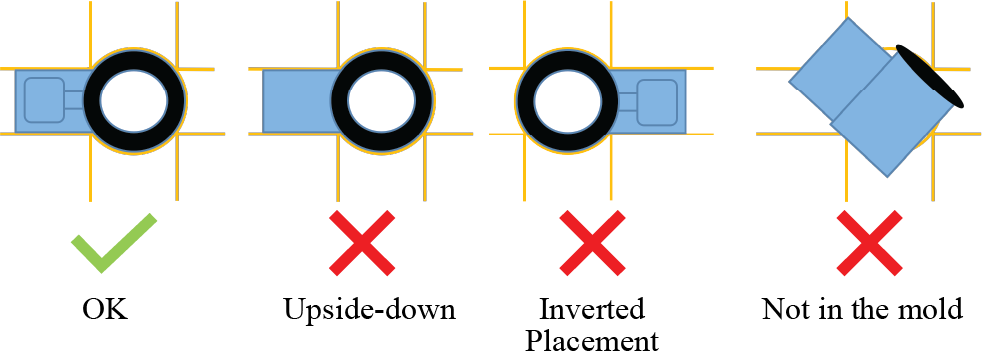

Inspection Requirements:

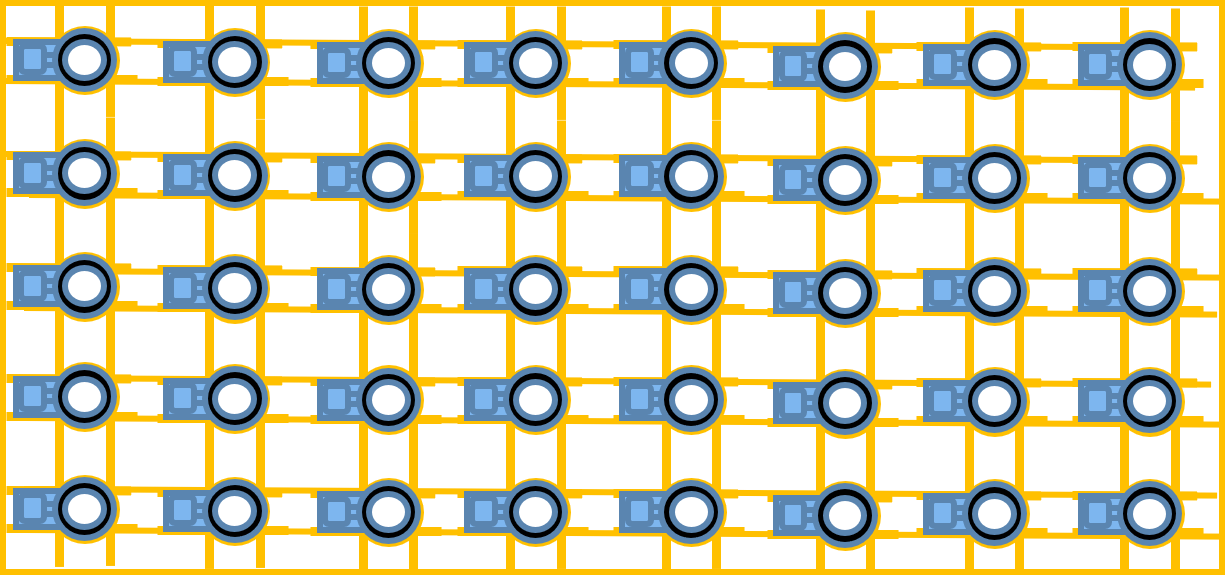

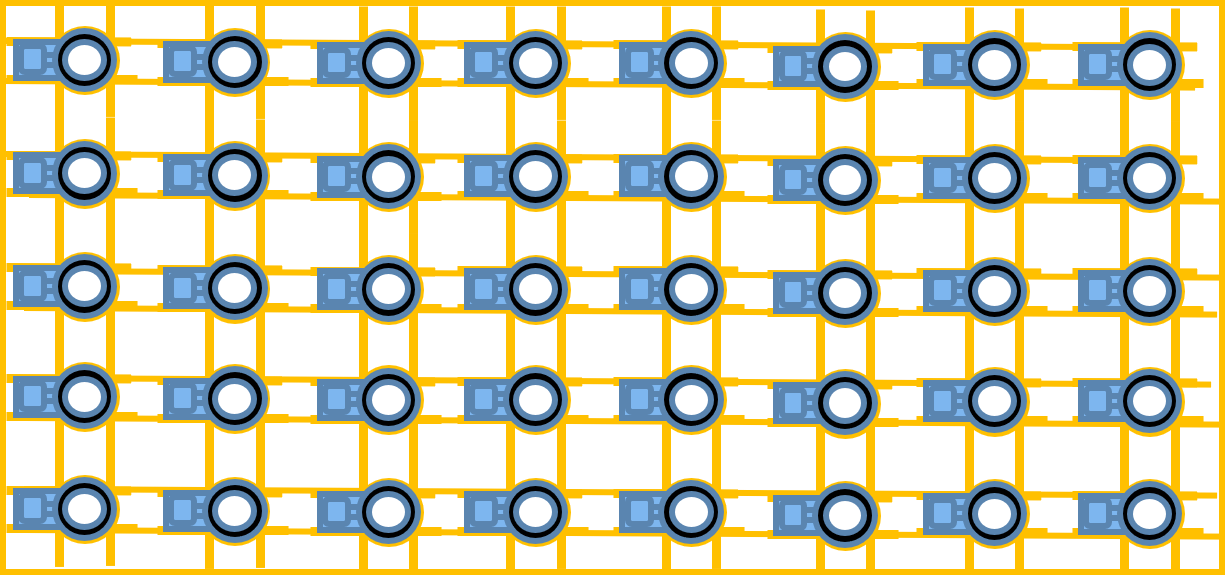

Tray dimensions

395mm x 210mm

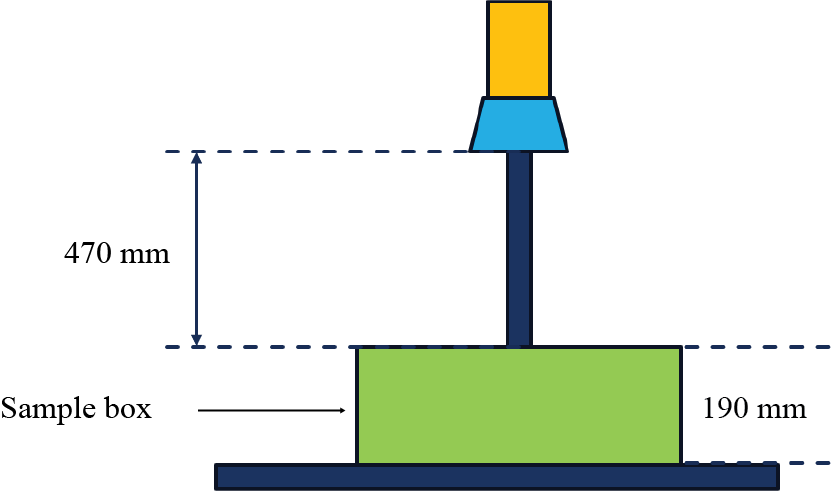

Use a camera to take a picture of the product in the tray.

It detects unconventional situations where the product is placed on the tray upside down, left and right, and judges it as NG.

Since the number of OK items is counted, it is possible to judge that the number of OK items is not acceptable because the number of acceptable items does not reach the specified number.

In addition, by having the AI software memorize unconventional situations such as upside down, left and right, and other unconventional situations, it is possible to determine what kind of NG has been detected.

-

Solution : Position detection and counting system

-

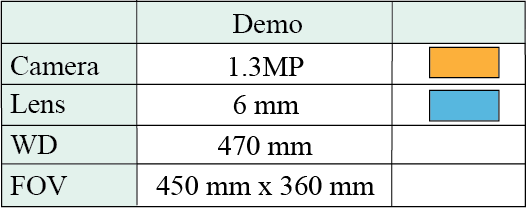

Hardware

A desktop computer with a graphics board capable of deep learning

6mm Fixed lens (working distance 470mm)

Software

AI-Detector can detect distortion and deformation of an object by making it memorize the object.

We will judge the distortion and deformation of the NG that you memorized this time.

If even one NG is detected, the result will be judged as NG.

-

-

AI software flow

Photograph data of the inspection target is taken using a camera.

Specify the inspection area for the product.

Obtain multiple OK images and multiple NG images.

At this time, the larger the number of NG images, the better learning will be possible. -

Test results and Notes

– It is possible to count the products placed on the tray.

– Products that do not meet the standards can be judged as NG.

– One inspection time of AI software is about 1 second

Specifications of the computer used

– CPU: Core i5 Gen 10 or higher

– Ram: 8GB

– GPU: RTX 3060

Notes

– This test was conducted in the office, and since the conditions are different from those on the production line,

it is necessary to install it on the production line and conduct further model training.

Since lighting is the biggest problem, it is necessary to provide lighting that can illuminate the production line in the same way.

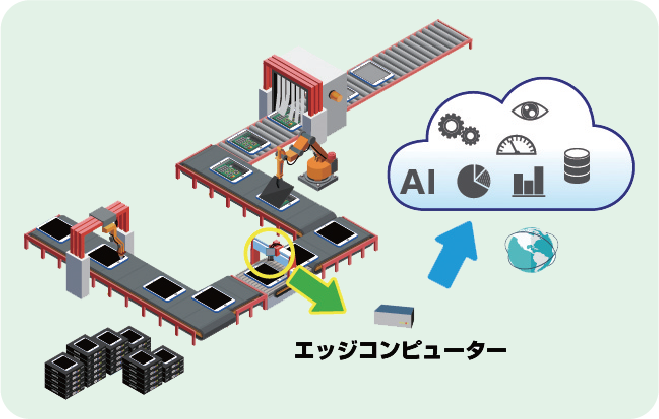

Examples of System Automation

How to introduce

-

STEP1

Please contact us by phone or E-mail.

-

STEP2

Evaluation of cameras, lenses, and lighting

Although it can be used with commercially available products, we also individually propose products that suit your company.

Demo version:You can download Demo version from here.

We also send CDs to those who cannot download. (Japan only)

Sample test:We accept sample test for free.

-

STEP3

Introduction