1.What is graphite nodularity rate?

Metal materials are used in all fields, and there are many types of metals.

Appropriate materials must be selected according to the application and purpose.

Cast iron is one of those metal materials.

Cast iron is a composite material in which graphite (nonmetal) is dispersed three-dimensionally within steel.

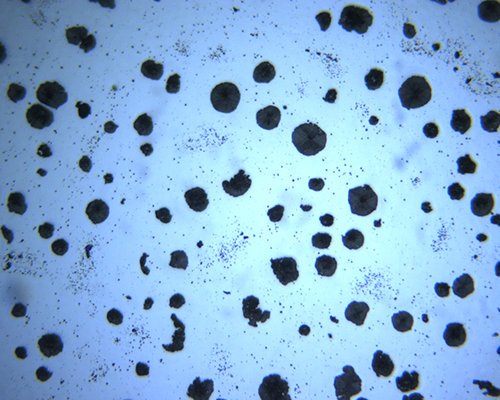

Depending on which form of graphite exists, mechanical properties such as tensile strength and elongation, and physical properties such as thermal conductivity vary.

In particular, mechanical properties such as tensile strength and elongation require an average graphite spheroidization rate of 80% or more when observed under a microscope (100x magnification).

Therefore, graphite nodularity is an important evaluation criterion to guarantee tensile strength and elongation.

2. Method of graphite nodularity analysis

To analyze the graphite nodularity rate, follow the steps below.

① Pre-treatment process: Rough cutting for large samples

②Pre-treatment process Resin embedding

③Pre-treatment process: Cutting the sample

④Pre-treatment process: Rough polishing of the cut surface

⑤Pre-treatment process Fine polishing of the cut surface

⑥ Pre-treatment process Buff polishing of the cut surface to a mirror finish

⑦ Pre-treatment process Etching treatment with chemicals (burning the surface with chemicals)

⑧ Microscope observation

⑨Classification, counting, calculation

There are many pre-processing steps and it takes a lot of time.

For observation, microscopic observation (100x magnification) is performed using a metallurgical microscope.

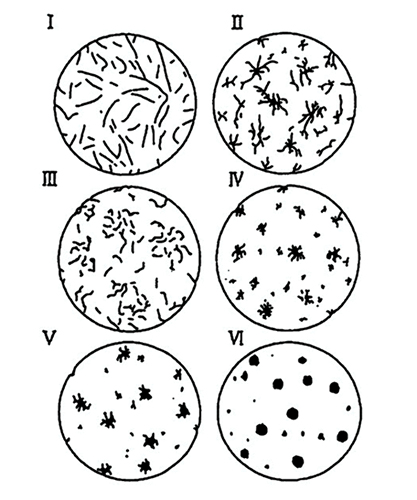

“We use classification based on roundness coefficients standardized by JIS industrial standards and numbers based on size.”

These are used to calculate the graphite nodularity rate, such as area calculation and counting.

Calculation of graphite nodularity in microscopic structure

① In principle, the magnification is 100x, and the test is performed on 5 fields of view, and the average value is calculated.

② Graphite and inclusions smaller than 2mm (actual size 20μm) are not covered.

③ Compare and classify with the classification table.

④ Find the ratio (%) of the number of graphite grains with shapes V and VI to the total number of graphite grains and use it as the graphite nodularity rate.

I will do it.

It is an analog method and requires complicated work and is time consuming.

Including the pretreatment process, the work requires a considerable amount of time and effort, is prone to human error, and is difficult to evaluate.

3.Improving the efficiency of graphite nodularity analysis

Therefore, we would like to propose a method using graphite spheroidization software.

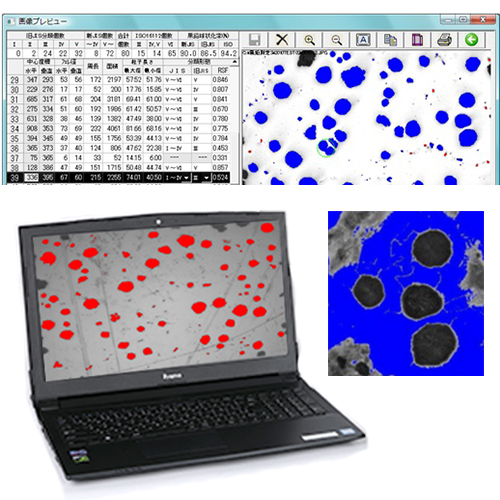

This is a method of clearly photographing spherical graphite magnified with a microscope and analyzing it using software.

This is done through image analysis processing according to the calculation method described above.

The image shows graphite spheroidized into various shapes and sizes.

In addition, it is possible to automatically measure the area and count graphite from the high-definition image.

Additionally, still images and accurate values can be output in Excel format, streamlining the entire process leading up to report creation.

Click here for details on graphite nodularity measurement software

|

黒鉛球状化率測定ソフト(日鉄テクノロジー株式会社製) KKS04 |

4. What is the set that can efficiently analyze graphite nodularity rate?

Recommended for those who want to analyze large cast iron, carry it around, and easily measure graphite nodularity!

●Set of small and simple metallurgical microscope (with camera) and graphite nodularity measurement software

|

Easy to observe large cast iron

|

|

|

|

|

Recommended for those who want to seriously measure graphite spheroidization rate!

●Set of metallurgical microscope, microscope camera, graphite nodularity measurement software

|

倒立型金属顕微鏡 (超高倍率顕微鏡) GR-29J-C3J |

|

|

|

|

|

|

|

|

5.Summary

It is efficient to use software to measure graphite nodularity.

We have convenient simple sets and full-scale sets available.