1. What is pretreatment for observing and measuring metal structure?

Pretreatment is required to observe the metallographic structure using a microscope.

Broadly speaking, the following four types of pretreatment are common.

2. Each pretreatment method

①Sample cutting

A large sample specimen is cut into small pieces using a cutting machine.

②Resin embedding

The cut sample is hardened with resin.

The reasons and purposes for embedding it in resin are as follows.

・Maintenance of sample edge shape

・Holds the shape of the sample so that it does not deform.

・Create a flat shape that is easy to observe

<Representative resins>

·acrylic resin

・Bakelite resin

·Epoxy resin

・Melamine resin

Each resin has different properties and colors, as well as different curing methods.

There are various types such as thermoplastic, thermosetting, natural curing, UV light irradiation curing, and two-component mixture curing.

The sample is placed in a cylindrical case and hardened with resin.

For heat curing, use a heating embedder, and for UV light curing, use UV light.

It may be omitted depending on the observation target.

③ Grinding and Mirror Finishing

The surface of the metal sample specimen is polished.

Generally, a grinding machine is used.

There are manual and automatic types of grinding machines, with the former being suitable for experts and the latter for beginners.

The manual type is prone to uneven polishing due to the force applied by hand to hold the sample, making it suitable for experts.

The automatic type, when the sample specimen is fixed to the sample fixing fixture, automatically polishes it, making it less prone to uneven polishing and suitable for beginners.

Rough polishing to precision polishing of the sample specimen is done using waterproof abrasive paper.

Polishing is done in wet conditions (while dripping water) from coarse to fine.

In precision polishing, the sample is finished to a mirror surface using cloth or buff polishing, diamond slurry, alumina powder, etc.

Therefore, it is necessary to change the grit of the waterproof abrasive paper many times.

There are single-layer and double-layer types of grinding machines, with the double-layer type being more expensive but convenient.

Once the mirror surface is achieved, the specimen surface is washed with flowing water.

After washing, it is dried using a dryer or similar equipment.

④ Etching Treatment (Surface Corrosion)

The polished surface of the sample specimen is immersed in etching solution (corrosive solution) suitable for the material and properties of the sample.

Etching treatment is performed for a duration that corresponds to the concentration of the etching solution and the material and properties of the sample specimen.

Example: For graphite spheroidization, a 3% nitric acid alcohol solution (Nital solution) is used.

After etching, rinse the sample specimen with water to remove the etching solution, then clean with ethyl alcohol or similar solvent before drying with a dryer or similar equipment.

|

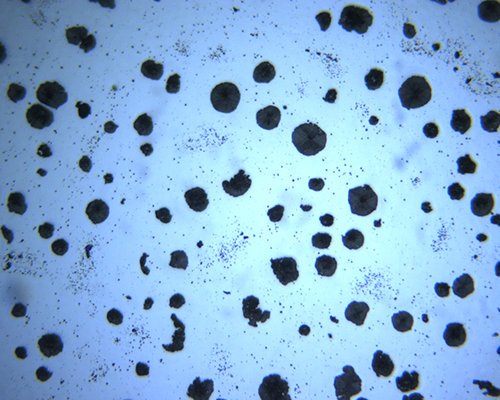

Graphite spheroidization rate before etching |

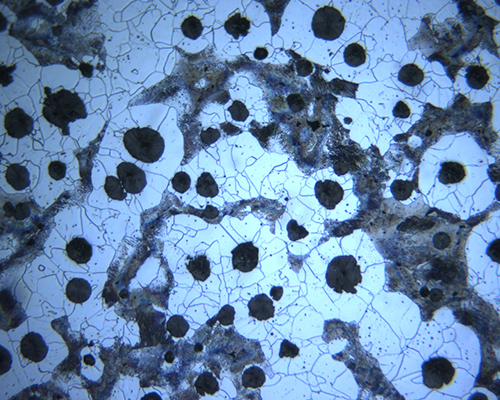

Graphite spheroidization rate after etching |

3. Microscopic observation of metal structure

After undergoing the aforementioned pre-treatment processes, the metal structure can finally be observed. The polished mirror surface of properly pre-treated sample specimens is observed under a microscope. By enlarging the structure and adjusting the focus, the metal structure is observed.

At our company, we offer “metal microscopes,” “microscope USB cameras,” and “sets combining metal microscopes and cameras.” Please refer to the following for product details.

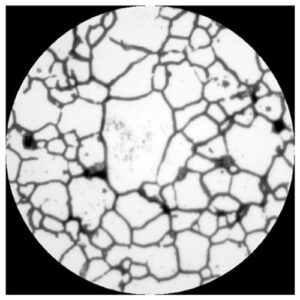

However, for advanced measurements such as observing non-metallic inclusions, measuring graphite spheroidization rates, and analyzing grain sizes (ferrite grain size, austenite grain size), specific measurement methods and counting techniques are utilized.

Observing metal structures requires appropriate pre-treatment processes, which can be time-consuming and labor-intensive. Therefore, it is recommended to efficiently perform these tasks in a shorter time frame using dedicated software.