1. What is grain size?

Depending on the metal material, its mechanical properties (resistance to external forces such as tensile and compressive shear)

The properties of the material are different, and it is necessary to use the metal material according to the application.

In addition, heat treatment changes the metallographic structure and its mechanical properties.

Therefore, this grain size analysis is an important test for product quality assurance.

2. How to measure grain size

(1) Visual comparison between standard drawings and metallurgical microscopes (comparative method)

(2) Simultaneous observation and comparison of eyepiece micrometers incorporated into a metallurgical microscope (comparative method)

(3) Incorporate an eyepiece micrometer into a metallurgical microscope and calculate it by simultaneous observation and comparison (cutting method)

(4) Using a camera, there are generally four patterns of soft particle size measurement (counting/quadrature method, cutting method).

3. Automatic measurement of metal grain size using software

Although it is the method (4) above, crystal grain size measurement can be performed automatically with software, and efficiency can be improved.

|

Metallurgical microscope |

|

USB 3.0 camera for microscope (5 million pixels) HDCT-500DN3 |

|

Particle Analysis Software G-S Measure (manufactured by NS Technology Corporation) |

4. More useful functions of grain size software

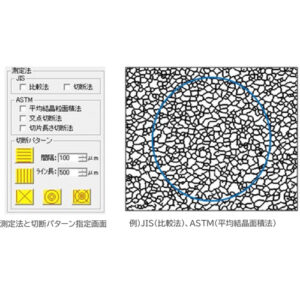

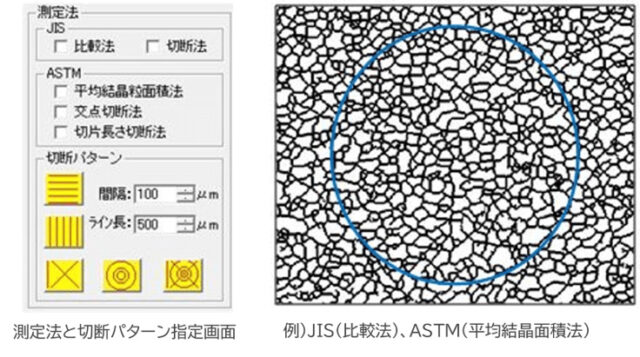

(1) Comparative method

This is a measurement method by visual inspection. Place a sample of metallographic structure under a microscope,

“Microscopic observation” and “Standard drawing of grain size (×100) JIS G 0551” and “Printed standard drawing”

Compare with an eyepiece micrometer (reticle).

This is the method of obtaining the grain size from the nearest standard diagram.

With this software, you can simply select a standard diagram while observing the microscope camera image in real time.

Calculate the grain size. Microscope camera images are superimposed on standard drawings in real time.

It is a useful feature.

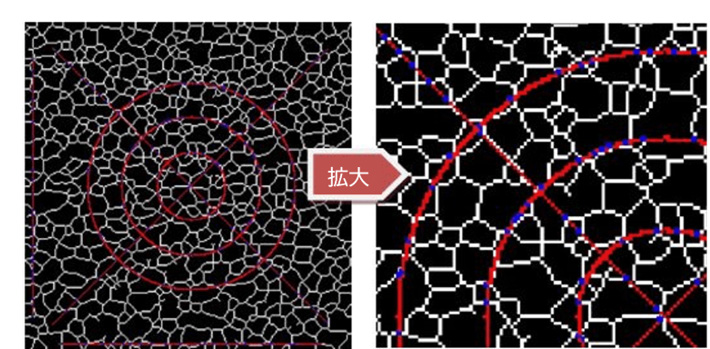

(2) Counting/quadrature method, cutting method

The cutting method is to write a pattern (test line) on the captured microscope image, and then

The average line segment length per grain when the pattern crosses the grain is determined, and the grain size is

This is how it is calculated.

< Measurement display example>ASTM (intersection cutting method, section length comparison method)

After measurement, the display shows in blue where the grain boundary rests on the cutting pattern.

* The image example measures a microscope magnification of 100x and a range of 1000 x 1000 dots.

5. Conclusion

If you have a lot of grain size measurement, this grain size measurement software has a convenient function

The trick to saving labor is to use it and measure automatically.